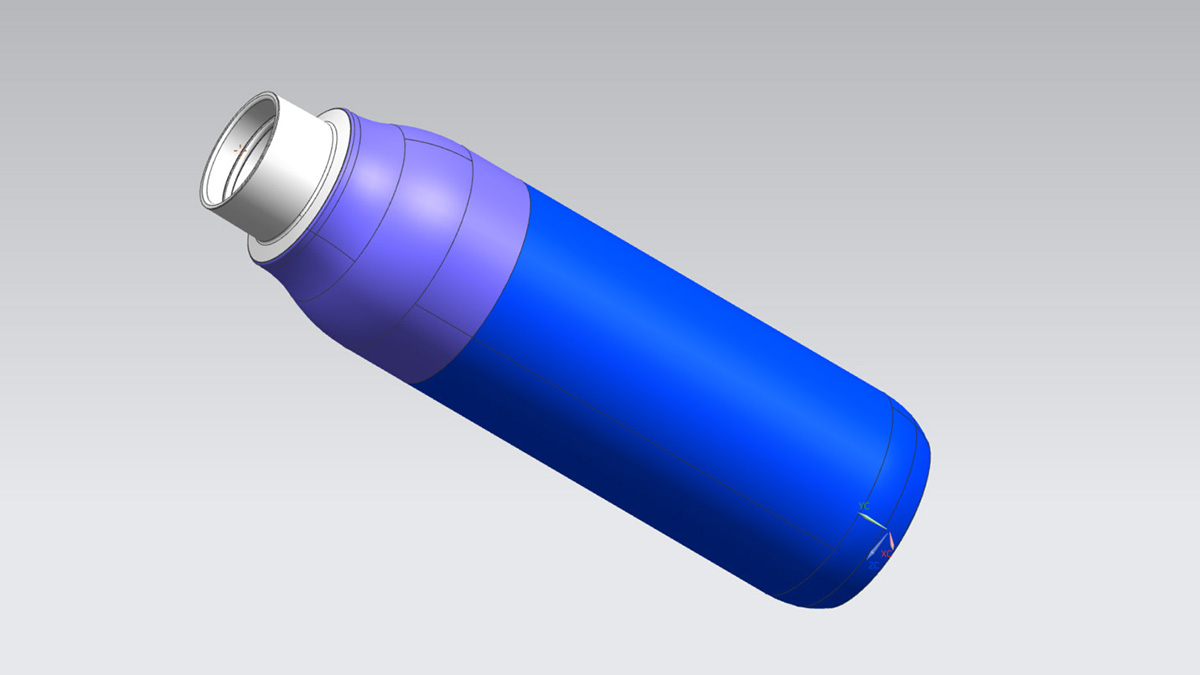

Insulated Stainless Steel Water Bottle Manufacturer

We specialize in one-stop manufacturing of custom drink bottles, tumblers, cups, coffee pots – delivering premium quality at competitive rates. Our designs prioritize innovation, timeless appeal, and ECO-friendly materials. We ensure your brand stands out with solutions built to last, resonate, and sustainable.

About KingStar

Custom Stainless Steel Water Bottle Manufacturer

KingStar is a highly specialized vacuum insulated stainless steel drinkware manufacturer. We develop and produce high quality stainless steel water bottles, tumblers, travel mugs, can coolers, food containers, beer growlers, dog bowls, reusable soap dispensers, lotion bottles and so on. KingStar products are excellent for home, office, sports & outdoors, outdoor recreation, camping, hiking and corporate gifts. Occupying 30,000 square meters, KingStar has more than 900 workers and is the leading water bottle supplier in China. Welcome OEM/ODM. We manufacture as per customers’ requirements – custom shapes, custom lids, custom colors, custom logos, custom packaging.

Cooperation Partners

News and Blog