After water bottles have been used for a period of time, the logo may easily peel off it or fade if the screen printing is of poor quality. Therefore, it is a must for water bottler manufacturer to strictly test the adhesion fastness of screen printing logos to eliminate the issue of logo peeling and logo wear.

The following are KingStar’s test methods and criteria for the adhesion of the screen printing logos on stainless steel water bottles.

1. The Thumb Test

Material Preparation: More then 5pcs stainless steel water bottle samples

Test Procedures: Fetch the sample, put your thumb on the printed picture and rub it back and forth 15 times with a force of 3+0.5/-0KGF.

Test Judgment: If the printed pattern of the product is notched, the stitches are broken or the adhesion of the ink is poor, the test then fails.

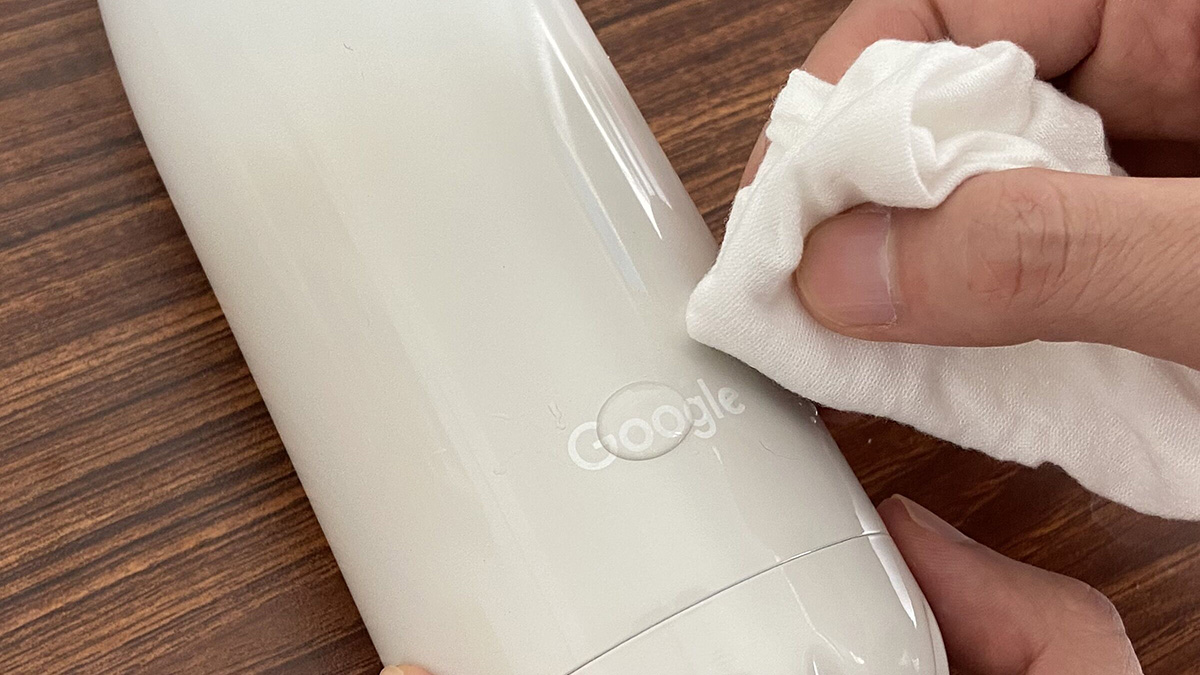

2. 75% Ethyl Alcohol Test

Material Preparation: 1. More then 5pcs stainless steel water bottle samples

- White cotton gauze

- 75% ethyl alcohol

- Fixture of 1.5+0.5/-0KGF

Test Procedures: Tie the bottom of the fixture of 1.5KGF with cotton gauze, dip it in 75% ethyl alcohol, and then use the white cotton gauze to rub the printed pattern back and forth 30 times (about 15 seconds) .

Test Judgment: If the printed pattern of the product falls off, or is notched, or the stitches are broken, or the adhesion of the ink is poor, the test then fails. Lighter color is tolerable yet the blurred pattern is unacceptable.

3. 95% Ethyl Alcohol Test

Material Preparation: 1. More then 5pcs stainless steel water bottle samples

- White cotton gauze

- 95% ethyl alcohol

- Fixture of 1.5+0.5/-0KGF

Test Procedures: Tie the bottom of the fixture of 1.5KGF with cotton gauze, dip it in 95% ethyl alcohol, and then use the white cotton gauze to rub the printed pattern back and forth 30 times (about 15 seconds) .

Test Judgment: If the printed pattern of the product falls off, or is notched, or the stitches are broken, or the adhesion of the ink is poor, the test then fails. Lighter color is tolerable yet the blurred pattern is unacceptable.

4. 3M Brand 810 Model Tape Test

Material Preparation: 1. More then 5pcs stainless steel water bottle samples

- 3M brand 810 model tape

Test Procedures: Apply 810 model tape completely to the screen printing logo, then quickly pull up the tape to the upward direction of 45 degrees. Repeat this procedure three consecutive times.

Test Judgment: If the printed pattern of the product is notched, or the stitches are broken, the test then fails.

5. 3M Brand 600 Model Tape Test

Material Preparation: 1. More then 5pcs stainless steel water bottle samples

- 3M brand 600 model tape

Test Procedures: Apply 600 model tape completely to the screen printing logo, then quickly pull up the tape to the upward direction of 45 degrees once only.

Test Judgment: If the printed pattern of the product is notched, or the stitches are broken, the test then fails.

6. 3M Brand 250 Model Tape Test

Material Preparation: 1. More then 5pcs stainless steel water bottle samples

- 3M brand 250 model tape

Test Procedures: Apply 250 model tape completely to the screen printing logo, then quickly pull up the tape to the upward direction of 45 degrees. Repeat this procedure three consecutive times.

Test Judgment: If the printed pattern of the product is notched, or the stitches are broken, the test then fails.

7. Gasoline Wiping Test

Material Preparation: 1. More than 5pcs stainless steel water bottle samples

2.White cotton gauze

- A mixture of gasoline and 75% ethyl alcohol (the proportion is 1:1)

- Fixture of 1.5+0.5/-0KGF

Test Procedures: Tie the bottom of the fixture of 1.5KGF with cotton gauze, dip it in the mixture of gasoline and 75% ethyl alcohol, and then use the white cotton gauze to rub the printed pattern back and forth 30 times (about 15 seconds) .

Test Judgment: If the printed pattern of the product falls off, or is notched, or the stitches are broken, or the adhesion of the ink is poor, the test then fails. Lighter color is tolerable yet the blurred pattern is unacceptable.

8. N-hexane Wiping Test

Material Preparation: 1. More then 5pcs stainless steel water bottle samples

- White cotton gauze

- N-hexane

- Fixture of 1.5+0.5/-0KGF

Test Procedures: Tie the bottom of the fixture of 1.5KGF with cotton gauze, dip it in the n-hexane, and then use the white cotton gauze to rub the printed pattern back and forth 30 times (about 15 seconds) .

Test Judgment: If the printed pattern of the product falls off, or is notched, or the stitches are broken, or the adhesion of the ink is poor, the test then fails. Lighter color is tolerable yet the blurred pattern is unacceptable.

If you need to have an exclusive water bottle manufacturer for you custom design drinkware, please write an email to sales@waterbottle.tech. We will reply within 24 hours.