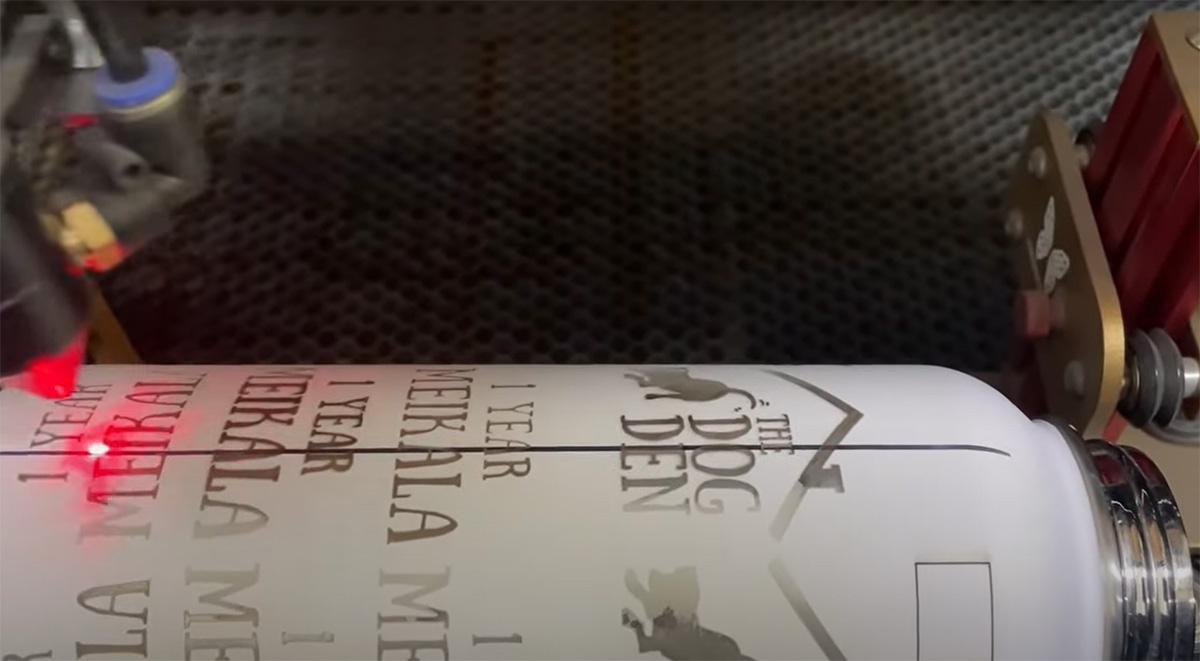

What are the precautions for using laser engraving machine? If you use laser engraving machines to customize logo/text/monogram/graphic/pattern for blank water bottles for a long time, what maintenance is important? This is a question that some laser engraving business owners and engineers often send emails to ask us at KingStar. As a leading custom water bottle manufacturer, we have compiled some precautions as follows. If you have any other questions or want to purchase wholesale blank water bottles or plain stainless steel tumblers in bulk, please send an email to sales@waterbottle.tech, you will get a reply within 24 hours.

Laser Engraving Machine Daily Maintenance and Notices

- Avoid touching the moving beam of the scanning table while the laser pointer is working.

- Laser and optical lens are fragile. Handle with care and avoid vibration while removing the machine.

- Stop it immediately and ask professional staff for help if the machine is out of order.

- Don’t turn on the laser marking machine under the situation of no water or abnormal water circulation.

- Pay attention to the switch order.

- The area of marking shall not be larger than the working area.

- Keep indoor and the machine’s surface clean and tidy.

- Keep the internal circulating water clean, clean the water tank regularly and change water with deionized or pure water.

- Wear goggles when working to prevent damage to myopia glasses due to strong light irritation.

- Don’t place your hands within the range of the laser scanner when laser is working.

- Don’t touch machine with wet hands for the safe use of electricity, wet hands cannot operate

- Keep your head and hands away from machine to prevent accidental injury during the whole operation of laser engraving.

- Please do not turn the system on and off frequently, and turn it on at least 3 minutes after shutting down

- Avoid frequent startup and shutdown. Power on at least 3 minutes after shutdown.

Laser Engraving Machine Environmental Requirements

The working environment must keep clean and dust-free all the time, with temperature at 15-30°C and humidity at 45-75%. Besides, ventilation equipment, no strong vibration and no heating body around are also key factors for machine’s working environment.

Laser Engraving Machine Machine Maintenance

- If water cooling is adopted to cool machine, non-viscous liquid like purified water, deionized water or distilled water is required, which needs frequent change.

- Keep workbench clean and tidy.

- Keep the rail of scanning bench clean and dust it with a soft-bristled brush.

- You can apply some lubricating oil to the wheel shaft when the slider of the scanning table doesn’t run smoothly. Regularly wipe reflectors and transparent mirrors with alcohol swabs.

- Lock the cover of the power supply to prevent falling metal objects, which damages the circuit;

- Pay attention to keep working environment sanitary since the scanning table is a precision instrument.

- Check whether the water cooling system is normal to ensure the safety of the laser before power on.

- Keep the optical path at a distance after turning on the laser. If the circuit or laser power fails, please ask a professional for repairing.

- Use casters and foot cups at the same time. Please support by foot cups when the machine is fixed, which can not only ensure the stability of the machine, but also avoid the deformation and damage of the casters caused by long-term friction.

- Power mains fluctuation should be less than 10%. If this can’t be guaranteed, a voltage regulator must be installed.

Click and read more: How To Start A Profitable Laser Engraving Business