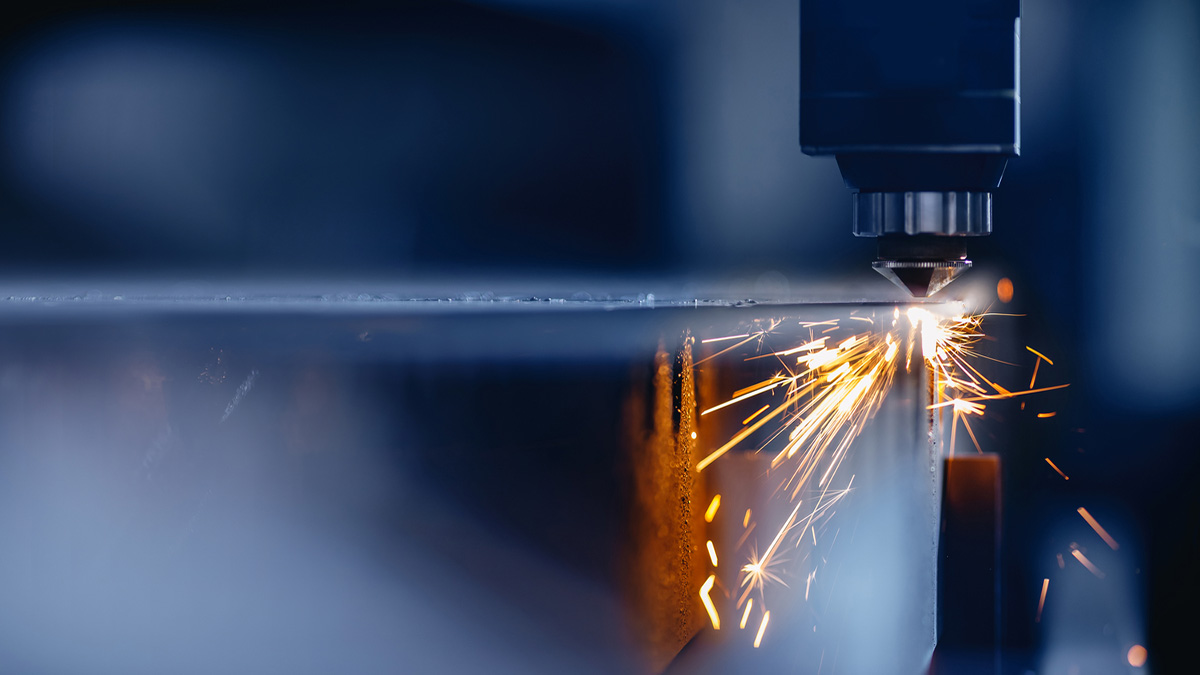

Laser marking technology has slowly penetrated into people’s daily life. We can see the traces of laser etching (that is laser lettering or radium engraving) on many things, like mobile phones, switches, keyboards, measuring tools, cables, sanitary ware, tableware, knives, fitness equipment, jewelry, thermos cups, wholesale stainless steel water bottles, custom metal tumblers, signs, various trinkets, electronic components, buttons, denim clothing, electrical appliances, cars, stoves, glass, crystal and packaging of various items.

Although the laser engraving / etching machine features with high stability and convenient use, it is inevitable to encounter various problems in daily use. For instance, uneven marking, a small problem commonly seen while marking, has a very large impact on the product. Due to the fact that uneven marking will directly affect etching quality, processing efficiency, product external image, and even the image of whole enterprise.

Reading this, many laser engraving business owners may want to know how to quickly fix these troubles, preventing the deterioration of marking quality and reducing the impact of output caused by equipment downtime. On this issue, as an experienced custom stainless steel water bottle supplier, KingStar has gathered some of the main causes and solutions for uneven etching for you:

1. Poor laser quality: The quality of the laser directly affects the quality of the laser beam. A low-quality laser may produce uneven etching.

Solution: Use a high-quality laser.

2. Incorrect machine position: If the galvanometer lens or field lens is not parallel to the processing table, the distance between the processed object (such as metal water bottles, tumblers, cups, flasks, jugs, growlers, food containers, dog bowls, and lunch boxes) and the laser beam passing through the field mirror will not be consistent, resulting in different energy density and uneven marking on the material.

Solution: Ensure the machine is placed horizontally until the galvanometer lens or field lens is parallel to the processing table.

3. Obstructed laser flares: If the laser head, stationary fixture, and galvanometer are not adjusted properly, some lens flares may be blocked when the laser passes through the galvanometer, leading to non-circular flares on the frequency multiplier after focusing by the field mirror and uneven etching effect.

Solution: Adjust the positions of the laser head, stationary fixture, and galvanometer.

4. Galvanometer signal issue: If there is a problem with the galvanometer signal or it is interfered with by external factors, the galvanometer may have slight glitter during the marking process, resulting in unclear etching text or pattern.

5. Material properties: The uniformity of the material and texture, consistency of the painting, spraying or coating thickness, or desynchrony of the oxidation time of the oxide parts can affect the absorption of laser energy by the material, leading to uneven marking.

Solution: Ensure the material is even/smooth before laser engraving.

6. Incorrect focal plane: If the product surface is not placed in the scope of the focal plane, uneven marking may occur.

7. Damaged galvanometer deflection lenses: If the laser beam cannot be reflected well when passing through the damaged area of the lens, inconsistent laser energy may result.

Solution: Replace the damaged field mirror and inner lens of the galvanometer promptly.

8. Rapid marking speed: Too fast marking speed can cause uneven etching, particularly for complex designs.

Solution: Slow down the marking speed or adjust the design for better clarity.

9. Laser beam attenuation: The laser beam may weaken if used for too long, resulting in uneven etching.

10. Bias marking: Using off-focus methods is easy to lead to a large-scale markup pattern, which is at the critical point of depth of focus or beyond the depth of focus range of the field mirror, resulting in uneven marking.

11. Off-focus marking: Similarly, off-focus methods may cause uneven marking by positioning the edge of a large-scale mark-up pattern beyond the depth of focus range.

12. Exceeding field lens range: If the content size of laser marking exceeds the scope of the field lens, you may encounter uneven engravings at the boundary.

Solution: Select a laser machine with appropriate power and matching field mirror according to the actual situation.

13. Inclined products: If the products or fixture are not placed horizontally, inclined, or parallel to the optical path, it can cause uneven marking.

Solution: Check whether the machine is placed horizontally and whether the product or fixture is tilted.

By addressing these potential causes of uneven marking, you can improve the quality and consistency of your laser engraving outputs.

Tips: If you encounter problems that you cannot solve while using the laser marking machine, never try repairing them by yourself, which will cause unnecessary losses. It is recommended that you contact the equipment supplier, or consult KingStar. We supply low price blank stainless steel water bottles and provide laser engraving technology consulting.