Looking to bring your unique water bottle design to life? Whether you’re a brand looking to create custom drinkware for your customers, a designer with a unique concept, or an individual with a vision for the perfect bottle, you need a reliable custom water bottle manufacturer to make it happen. As a leading factory of wholesale custom stainless steel containers, we specialize in turning your ideas into functional, stylish, and durable products. In this article, we’ll explore how to help you create the perfect drink bottle, tailored to your exact needs, from concept to production. Let’s dive in and discover the possibilities!

Custom Metal Bottle Manufacturing

Customization Options

At KingStar, we believe your water bottle should be as unique as you are. That’s why we offer a full range of personalization options, including material selection, size/capacity, caps/lids, logos, molding, decorating, and packaging. Let’s take a closer look at what we can do for you.

1. Custom Materials

First, KingStar offers a variety of materials, including different types of stainless steel, plastics, silicone, etc. Each part of your water bottle can be crafted from the material that best suits your design vision and functional needs. Whether you’re looking for the durability of stainless steel, the flexibility and comfort of silicone, or the lightweight convenience of plastic, we’ve got you covered.

2. Custom Size/Capacity

Any customized size or capacity.

3. Custom Caps/Lids

KingStar offers a wide range of custom caps and lids to complement your water bottle design. Choose from options like the flex cap, straw lid, sports lid, handle lid, stainless steel cap, spout lid, and flip lid, each designed for convenience, style, and functionality. Whether you need a secure seal, easy drinking access, or a more active, spill-proof solution, we have the perfect lid for every lifestyle.

4. Custom Logos

Make your water bottle truly yours with a custom logo or monogram. At KingStar, we specialize in OEM and ODM stainless steel sports water bottle manufacturing services, designed to elevate your brand identity. We offer a variety of logo options, including printing, engraving, and labeling, allowing you to showcase your brand in the best possible way. Simply send us your logo files in AI or EPS format, and our expert sales team will guide you through the entire process to ensure your vision is perfectly executed.

5. Custom Molding

With over 20 years of experience in developing and manufacturing stainless steel insulated thermoses, KingStar has the expertise to custom mold bottles in a variety of shapes to meet your specific needs. From designing custom molds for the bottle shape and caps/lids to incorporating electronic modules for smart functionality, we have the capabilities to create innovative and tailored products that align perfectly with your design and functional requirements.

6. Custom Decorating/Graphic

KingStar offers numerous coating and printing methods for insulated metal drink bottles. Simply send us your desired color Pantone code, and custom graphic artwork in EPS or AI format, and we’ll help turn your concepts into aesthetic products.

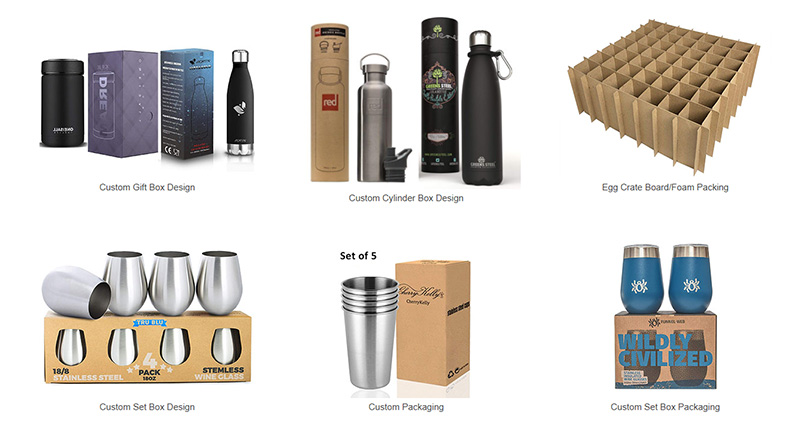

7. Custom Packaging

To better help enhance our client’s brand value, KingStar provides a complete range of packaging materials, including gift boxes, display boxes, bubble bags, UPC sticker labels, hang tags, etc. Custom-designed graphics on packaging are also available.

Why Partner with Us

KingStar has delivered countless high-quality, durable products. We pride ourselves on our stringent quality control procedures, ensuring that every product meets the highest standards. In addition, we offer short lead times, so you can receive your products quickly without compromising on quality. Moreover, our low MOQ allows us to support businesses of all sizes, making it easier for you to start with smaller orders and scale as your needs grow.

Beyond just product delivery, we emphasize a customer-centric approach, with a prompt response from our dedicated team, always ready to guide you through every step of the process. With rich experience in the industry and in-house R&D support, we are equipped to help transform your innovative ideas into tangible products.

There are some main factors affecting the manufacturing cost of stainless steel water bottles. More details are outlined as below:

1. Materials

The cost of material is often valued in per g. The main materials costs for stainless steel water bottles are:

- 18/8 Stainless steel: $0.005 / g

- 316 Stainless steel: $0.006 / g

- 201 Stainless steel: $0.0045 / g

- Polypropylene: $0.002 / g

- AS: $0.0025 / g

- TRITAN: $0.005 / g

- Silicone: $0.003 / g

2. Different Order Quantities

Generally, you can get more discount by ordering more qualities. See the figures below:

- MOQ 3000PCS

- 10000PCS (1% cost down)

- 30000PCS (2% cost down)

- 50000PCS (2.5% cost down)

- 100000PCS (3% cost down)

- 500000PCS(3.5% cost down)

3. The Timing of Your Order

Generally, the price will be higher if your order is urgent.

4. Manufacturing Process-copper Plating Process

Copper plating on the outer layer of the inner tank: USD 0.2/ unit.

3. The Timing of Your Order

When your lid order quantities are small, and you want them urgently, the price would be higher than usual.

Equally, when it is one-time order and is with urgent time, the price also would be higher than usual.

5. The Cost of Different Surface Decoration:

No plate charge cost when only applying different Pantone colors with spray painting, powder coating, or UV plating.

The plate charge cost occurs when different graphic decorations are needed with different techniques, such as logo printing, logo embossing, heat transfer, etc.

The plate charge cost ranges from 50 USD to 600 USD, and the sample lead time takes 1-2 weeks.

Cost lists for different surface treatments of stainless steel water bottles:

- Spray painting: 0.15USD/each color

- Powder coating: 0.40USD/each color

- Heat transfer printing: 0.15USD(painting base) + 0.10USD (printing)

- Sublimation transfer printing: 0.60USD + plate fee USD600

- Water transfer printing: 0.40USD

6. Private Label-custom Logo Technology

- Silk Screen logo(single color): 0.03USD

- Silk Screen logo(two colors): 0.07USD

- Laser engraving logo: 0.05-1.15USD (depending on the size of the logo)

- Embossing/debossing logo: Need to build new tooling to achieve. The pricing depends on logo size and how complex the logo.

- Emblem logo: 0.3USD – 3 USD(depending on badge material and size)

- 3D printing logo: 0.1USD-0.2USD(depending on how complex of the logos and the size of logo)

7. Packaging Methods

Furthermore, custom design packaging requires additional cost.

- Square white box: 0.1USD

- Square color box: 0.2USD

- Cylinder color box: 0.5USD

- Display box: 0.4 USD-0.5 USD depending on the design.

Above all, the cost of manufacturing custom stainless steel water flasks depends on various factors, from design to delivery. Even trivial expenses, such as labor and logistics, can impact the overall cost. Tal Water Bottles, Tal Coffee Tumbler Cups Review

Conclusion

In conclusion, KingStar is your reliable partner in bringing your custom water bottle designs to life. With our comprehensive range of services, we’ll help you create unique, functional, and high-quality products. As a leading expert in manufacturing custom-designed stainless steel gym bottles, our expertise, dedication to quality control, and customer-focused approach ensure that we deliver products that meet your exact specifications.

Lastly, for more information, feel free to send us a message online or via email to sales@waterbottle.tech. We will reply as soon as possible.

Wholesale Journey Water Bottle Ceramic Coated, Unit price: USD 2.99