Custom Manufacturing

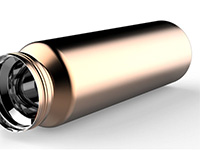

KingStar provides custom manufacturing services. We have rich experience in manufacturing water bottles with custom shape, custom lids, custom patterns, custom colors, custom imprints, custom logos and custom packaging, etc. Founded In 2002, KingStar is a leading vacuum insulated stainless steel water bottle manufacturer. We focus on developing and manufacturing high quality metal water bottles, tumblers, flasks, coffee cups, travel mugs, coffee pots, wine bottles, food containers, beer pints, beer growlers and other vacuum insulation stainless steel drinkware / containers. Occupying 30,000 square meters, KingStar has more than 900 workers and is the most reliable water bottle supplier in China.

We have in house designers and experienced engineers working for OEM and ODM projects. Our engineer team can turn your hand drawing or even design idea into 3D drawing and finally provide you the 3D printed prototype sample. Our skilled Research & Development team expands our product range to meet your every need and the changing market trends. KingStar helps brand owners, dealers, and wholesalers significantly increase profits.

KingStar Production Process

Shape Forming

Cutting

Welding

Polishing

Copper Plating

Powder Coating

Transfer Printing

Laser Etching

Inspection

Assembly & Packing

KingStar Manufacture Facilities and Equipment

CNC Molding Center

Plastic Injection Molding Line

Shape Forming Machine

Laser Welding Machine

Air-tightness Test Machine

Vacuum Making Machine

Automatic Polishing Machine

Powder Coating Machine

Insulation Test Machine

Assembly Line

Torque Tester

Salt Spray Tester

Printing Life Tester

Precision Temperature Tester

Humid & Temperature Tester

Your Custom-designed Stainless Steel drinkware Manufacturer Factory In China

Custom Water Bottle Tumbler Manufacturing Project Processes

Step 1: Sign NDA

NDA is the abbreviation of Non-Disclosure Agreement. Before you expose any confidential information (such as drawing or design concepts) about your custom water bottle project, we sign NDA with you.

Step 2: Complete Design drawing

Basing your drawing, our engineering team will release DFM (Design For Manufacturing) report and help revise the drawing. If you only have a design concept but without drawings, our R&D team offers design support to complete the drawing.

Step 3: Quotation & Payment

After having all your requirement, we quote for both tooling cost and product pricing. Payment term for tooling is that, 50% deposit and 50% after sample approved by you. Payment term for mass production is normally 30% deposit + 75% balance before shipment.

Step 4: Tooling Fabrication & Sample Approval

Lead time of tooling fabrication is 5 weeks. You will get 3D printed prototype sample to finalize the design, and T1, T2 samples for final approval on your custom mold design bottle tumblers.

Step 5: Mass Production

After T2 tooling sample approval and receiving deposit payment, we start mass production. The lead time of mass production is 45 days. It’ll be even longer for custom design smart water bottle projects.

Step 6: Final Payment & Shipping

After receiving final payment, we will work with your forwarder to arrange the shipment. If you have no experience in importing from China, we can handle the whole logistics and arrange globally door-to-door shipping.