Blog

Share the knowledge of water bottle manufacturing process, the research and innovation of thermal insulation technology, and the application of Industry 4.0 in the vacuum flask manufacturing industry.

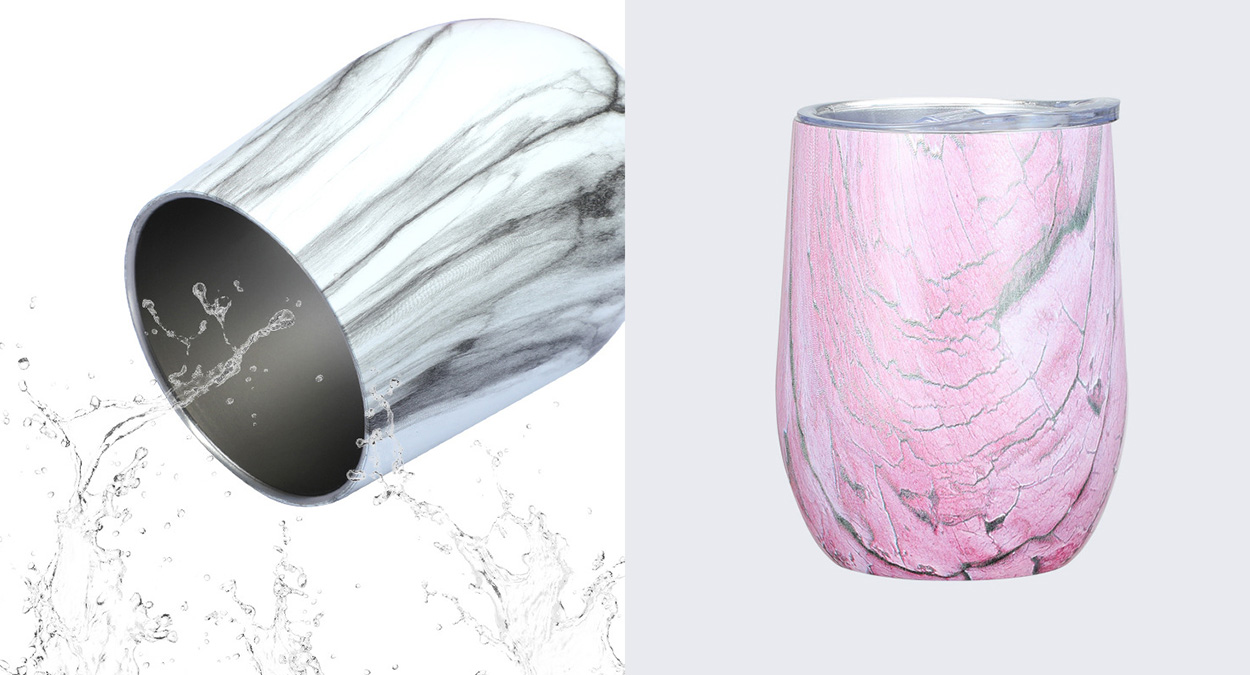

Reusable stainless steel water cups are gradually replacing plastic water cups and become a trend because of their BPA free and ECO-friendly characteristics. KingStar is increasingly using recycled marine plastics in products. Environmental protection is like our quality management philosophy, which is deeply reflected in every water bottle.

KingStar – Stainless Steel Tumbler Cup OEM Manufacturer

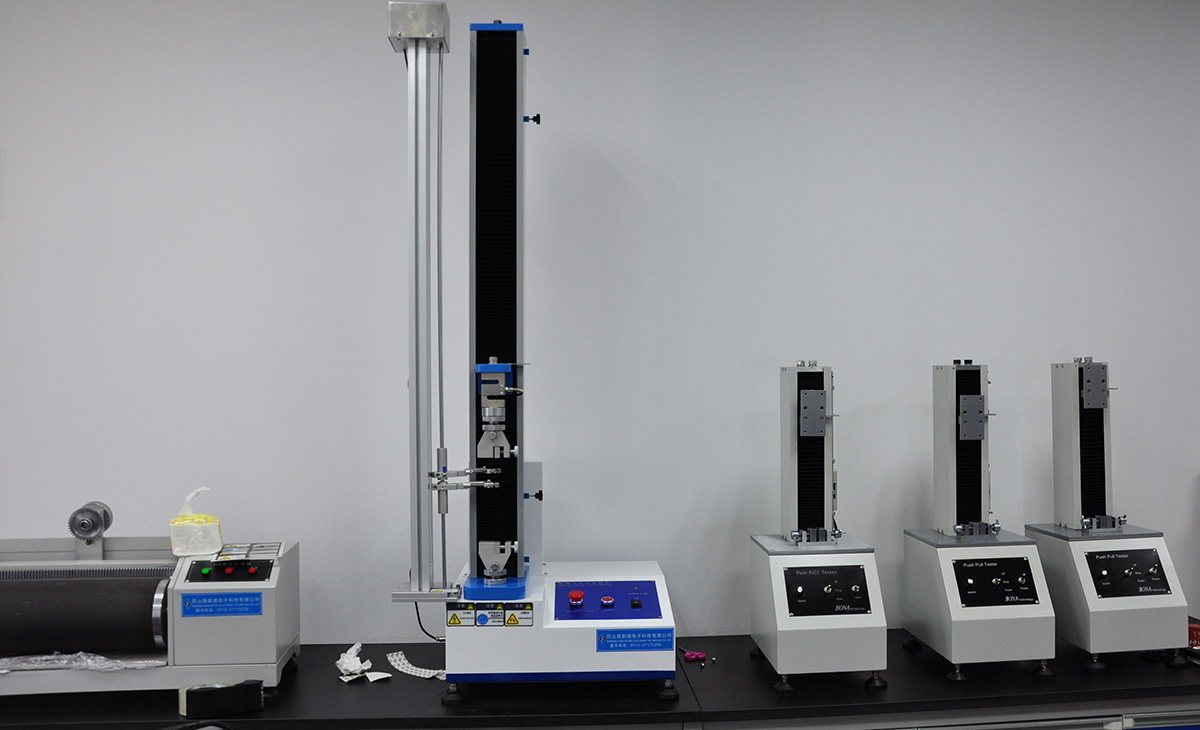

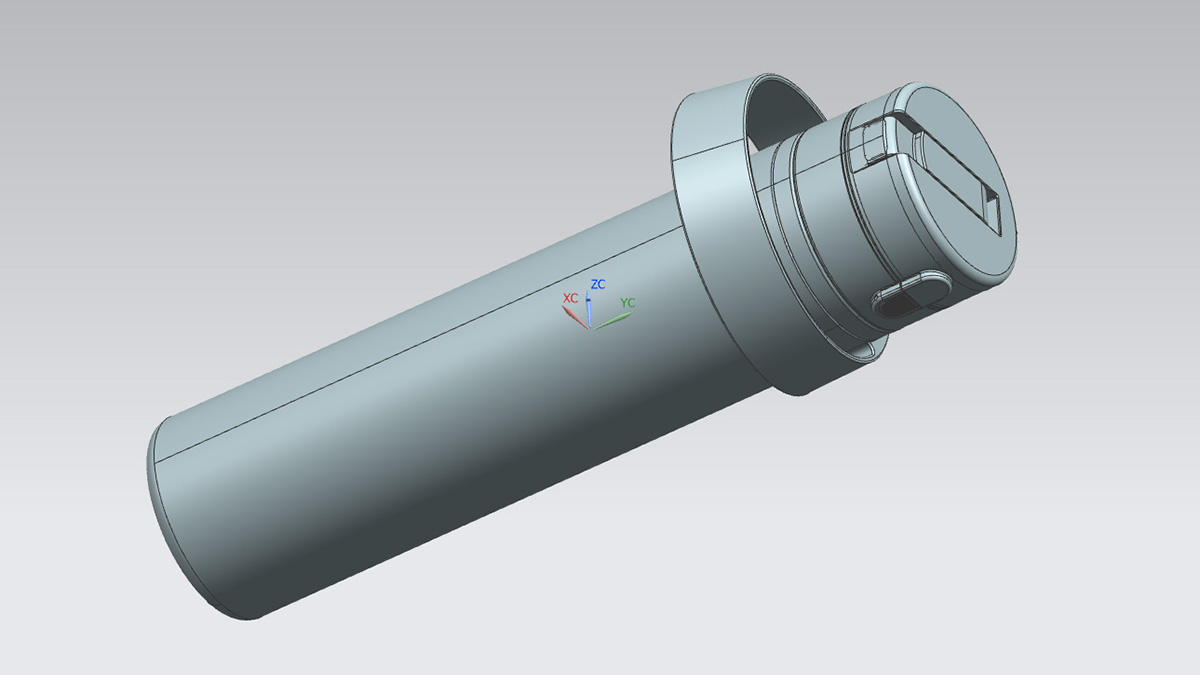

KingStar was established in 2002, and we have become one of the top stainless steel water bottle OEM manufacturer. Besides serving major customers and well-known brands in the world, we also offer our best service to start-ups. Our R&D team has rich experience in concept design and mold development, and our manufacturing team also boasts professional production and quality control, moreover, you can enjoy 24/7 uninterrupted service of our sales team . With strenuous efforts for years, our products have covered various drinkware such as insulated metal tumbler, mug, cup, can cooler, food container, beer growler, pet bowl, etc. Our company has made great achievements in the fields of medical packaging and precision electronics. The vacuum flasks developed by our company have been widely applied in high-end medical equipment. We are a company with great potential, with a monthly output of 600,000 pieces and 30,000 square meters area for production facilities. You are welcomed to contact us on your custom water bottle project and we are looking forward to establishing a long-term business relationship with you!