Logo printing is an important part of KingStar’s customized stainless steel water bottle tumbler OEM manufacturing service. The main logo making technology of stainless steel water bottles: silk screen printing, laser engraving, digital printing, 3D printing, embossing, debossing, metal emblem, tag etc.

For more detailed information about options for stainless steel water bottle logo making, please click here: Custom Water Bottle Logos

Stainless steel water bottle logo screen printing process mainly includes two steps: printing and baking. Proper baking temperature and time can ensure the fastness of the logo and ensure that it will not fall off during subsequent use.

The following is a detailed introduction of the silk screen process.

Screen printing is to stretch synthetic fiber fabric, metal mesh or silk fabric on the screen frame, and then make the screen printing plate through photochemical plate making or hand engraving paint film. With the help of the screen printing technology today, a silk screen can be made through photosensitive materials in photoengraving (to make the hole of silk screen of the graphic part on the silk screen unblocked holes, and screen hole of the non-graphic part blocked).

Basic introduction

In the process of printing, the squeeze of the squeegee makes the ink transferred to the substrate through the mesh of the graphic part, forming the same graphic and text as the original. The equipment of screen printing is not complicated, low in cost, convenient to operate and print, easy for plate making and excellent in adaptability. Screen printing is widely applied in: color oil paintings, business cards, posters, product signs, binding covers, printed and dyed textiles, etc.

In terms of environmental protection, silk screen printing is a polluting process. First of all, the developer can be produced during the plate making, and the ink used makes the ink tank left, and waste water or waste rags are produced during cleaning.

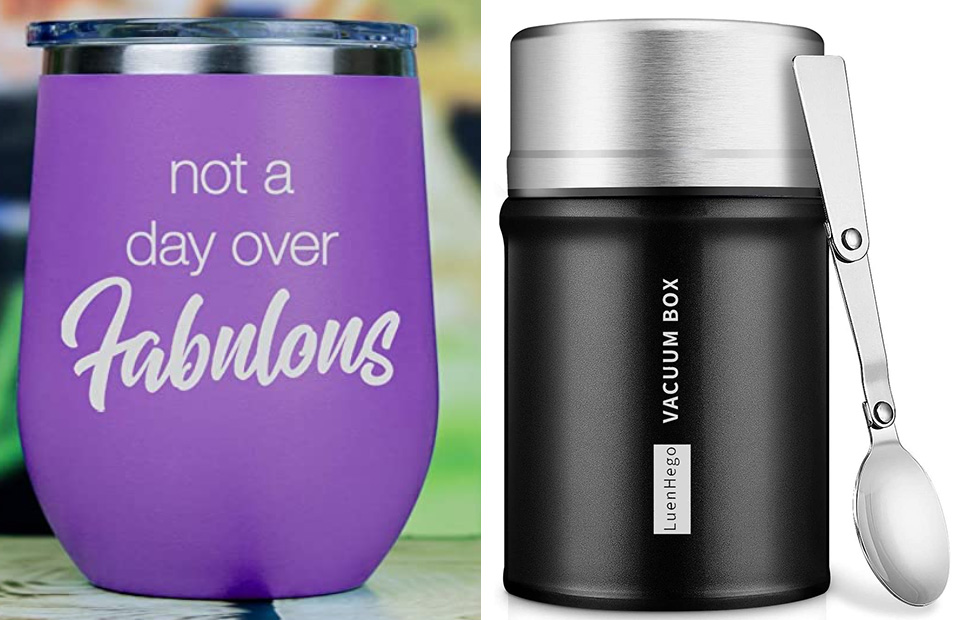

stainless steel water bottle tumbler cup silkscreen printing process

Principles of screen printing

Screen printing is composed of five parts: screen printing plate, ink, printing table, squeegee and substrate. The fundamental of screen printing: make the ink through the mesh of the graphic part while keep the non-image and text part impermeable to the ink. To do printing, you should pour ink on one side of the screen printing plate, and press on the ink on the screen printing plate through a squeegee while inching toward the other end of the screen printing plate. In this process, the ink is squeezed by the squeegee from the mesh of the graphic part to the substrate. Thanks to the viscosity of the ink, the imprint can be fixed within a certain scale. During the printing, the squeegee always contact with the the substrate and screen printing plate in line, and the contact line moves with the squeegee. Due to the gap between screen printing plate and the substrate, the tension of screen printing plate produces a reaction force (resilience) against the squeegee. The resilience makes the screen printing plate contact with the substrate in mobile line while the other parts of the screen printing plate are disengaged with substrate. The ink and the screen are to be broken to enable the size accuracy of printing and avoid staining the substrate. With the lift of squeegee after scraping across the whole layout, the screen printing plate is also lifted as well, then gently scraped the ink back to the original position. So this is a stage of printing.

Screen printing application performance

Screen printing must accurately reproduce the graphics and tones of the original manuscript like other printing. Generally speaking, the manuscripts used in screen printing not differ greatly from those used with other printing methods, but requirements are different in specific plate making and printing practices, which is mainly determined by the characteristics of screen printing. Especially considering the thick ink layer and bright color of screen printing, we must take the special effects of screen printing into account when selecting manuscripts and plate making.

In addition, the requirement for the graphic lines and dot accuracy of the manuscripts used in screen printing are also different from those of the manuscripts used in ordinary printing methods. If the lines and dots of the manuscript are very fine, it will be very difficult to make a plate by screen printing. Therefore, screen printing is not suitable for reproducing original manuscripts with fine lines and dots. So we must fully consider the characteristics of various printing in choosing a printing method. And attention should be paid to selecting the appropriate screen line even in the screen printing plate making so that fully reproduce the original manuscript.

Screen printing is more suitable for single color manuscripts with crisp text and lines, and it is also suitable for colorful and clear manuscripts with large contrast. Through the screen printing, the reproduction can become rich in expressiveness. Through contrast of the rich and thick ink layer and the of light tones, the texture and three-dimensional effect of the original content can be fully expressed.

There are two types of screen printing photoengraving manuscripts: reflective manuscripts and transmissive manuscripts, and the former are often used. transmissive originals are mostly used in color photography.

Screen printing mainly uses positive pictures to make screens version. But requirements for manuscripts vary with different plate making methods.

Main features of screen printing

The features of screen printing can be summarized as follows:

①Screen printing can use many types of inks, such as oily, synthetic resin emulsion, water-based, powder and other types of inks.

②Soft layout. The layout of screen printing is soft and flexible, which is not only suitable for the print on soft objects like cloth and paper, but also for printing on hard objects, such as glass, ceramics, etc.

③Low printing force of silk-screen printing. Since the pressure in printing is small, it is also suitable for printing on fragile objects.

④The ink layer is thick so it can adhesive to the objects in full scale.

⑤It is not restricted by the surface shape and size of the substrate. We can know that screen printing can not only print on flat surface, but also on spherical or curved surfaces; it is suitable for printing on both small objects and larger objects. This printing method is flexible and widely applicated.

Main applications of screen printing

Screen printing boasts very wide application. Any object can be applied as a substrate except water and air (other liquids and gases are also included). Someone once said about this screen printing: If you want to find an ideal printing method in the world to achieve your purpose, screen printing might be your first choice.

Specifically, the main applications of screen printing are as follows:

①Paper printing

②Plastic printing

③Wood products printing

④Metal product printing

⑤Glass and ceramic products printing

⑥ Signs

⑦Circuit board printing

⑧Printing and dyeing

⑨Leather product printing

⑩Printing of electronic products

Click here to read more about Vacuum Insulated Stainless Steel Water Bottle Tumbler Manufacturing Process

At present, most of the stainless steel water cups/tumblers on the market adopt the two methods of screen printing logo or laser printing logo. Compared with laser-printed logos, screen printing logo is able to produce multi-color logos. As we all know, the logo printed by laser can only be single color. If you have any questions about insulated water bottle manufacturing, you are welcome to contact KingStar, the most reliable stainless steel water bottle manufacturer.