Have you ever wondered how insulated cups work? There are many options when choosing an insulated cup, thermos bottle or insulating tumbler. If you don’t know what double wall vacuum insulation means, or why vacuum insulation is better than foam insulation and air insulation, then you are in the right place! It is important to know the facts before making the final purchase.

Vacuum insulation between double walls in a thermos bottle is one of the best ways to keep the coffee hot for a long time. The principle seems relatively simple. The vacuum layer is to prevent heat from escaping and cold from entering. But there are some serious physical phenomena under the lid.

This article explains in detail how heat is transmitted, and why the coffee becomes cold.

What Does Vacuum Insulation Mean?

Vacuum insulation means that your insulated cup has a vacuum insulation layer between double walls of stainless steel. The existence of the vacuum layer makes it difficult to conduct heat.

Why You Should Buy a Stainless Steel insulated Cup?

The insulated stainless steel cup is a good choice, especially in summer. Sip in a stylish and efficient way, because you can enjoy the drink at the right temperature all year round.

Billions of disposable coffee cups are produced every year, and after using them once a day, millions of coffee cups are eventually buried in landfills. Poor waste management and a limited number of recycling plants push these wastes into our oceans.

It’s time to change our daily lives, which is not only good for us, but also good for the environment. Check out the number one reason why we must have reusable stainless steel thermos flasks.

- BPA Free & Non Toxic

- Keep the coffee hot

- Fit big ice cubes & Keep drinks cold

- Excellent for tea bags

- Durable for everyday use & No Condensation

- Environmental friendly

- Looks cool

- Easy to clean

- Car cup holder friendly

Keeping beverages at the right temperature, then double wall vacuum sealed cup bottle is the best choice. In the long run, a well-designed multi-purpose vacuum flask can not only save money, but also protect the environment.

Why is Vacuum Insulation Important for Travel Mugs?

Why does your cold drink get warmer? Why does the coffee get cold in the first place?

The answer lies in the difference between the temperature of your cold drink or coffee and the room temperature. Due to the huge difference between the two, heat is quickly transferred from the pot or cup to the room.

However, if coffee is poured into a vacuum insulated travel mug, rapid heat transfer can be prevented. In this way, when you open the cup a few hours later, your cold beer is still ice cold, and your hot coffee should still be hot.

The Best Insulated Tumbler Cups: From the Manufacturer’s Point of View

The materials of insulating cups are very standard. Food grade 18/8 stainless steel are mostly used. You won’t find many designs deviate from stainless steel because it provides excellent temperature control and is easy to clean. In addition, the temperature control of hot and cold beverages, whether it is splash-proof, easy to clean, design durability and comfort are also key factors

From the professional point of view of the insulated cup manufacturer, combined with the popularity of the market, we have compiled a list of the best insulated stainless steel cups in bulk.

- Yeti Rambler tumbler 20oz and 30oz

- Beast insulated coffee cup 30oz

- Hydro Flask 22-Ounce Insulated Tumbler Cup

- Klean Kanteen Insulated Tumbler With Straw

- S’well insulated cup

- Chilly’s insulating mug cup

What Material is the Thermos Insulating Cup Made?

The body of the insulated cup is usually made of 18-8 stainless steel. We are also familiar with it as SUS 304. It is widely used in food containers, kitchen products, and has good corrosion resistance, recyclability, and environmental protection.

The lid of the vacuum flask is usually made of BPA free PP material and Tritan. Yeti’s Rambler cup also has magnet material.

The sealing ring and anti-slip pad at botton are made of food-grade silicon.

Click and read more: Difference between stainless steel SUS304 and SUS201 thermos flask

Why Can’t the Thermos Cup be Made of Aluminum?

Reason as below:

1. Aluminum is a good conductor of heat, and its thermal conductivity is three times larger than that of stainless steel, so aluminum cups have poor thermal insulation capabilities.

2. The hardness of metal aluminum is low. If the insulation cup is made of aluminum, the wall thickness needs to be more than 1mm, otherwise it will be deformed under the pressure of air. If the wall thickness reaches 1mm, the volume of the water cup is bloated and portability is not good.

3. Aluminum will accumulate slowly in the human body, and the toxicity caused by it is slow and difficult to detect. Once the toxic reaction of metabolic disorder occurs, the consequences will be very serious.

How Does Vacuum Insulation Work?

There are three ways of heat transfer: heat conduction, heat radiation and heat convection. Heat transfer (or heat travel) is a physical phenomenon in physics.

- Heat conduction is the phenomenon of heat energy transfer caused by temperature difference. In heat transfer, heat is used to measure the change in internal energy of an object.

Heat conduction is a process in which a large number of molecules, atoms, etc. collide with each other to transfer the internal energy of an object from a higher temperature part to a lower part. Heat conduction is the main way of heat transfer in solids. In gases and liquids, heat conduction is often carried out at the same time as convection.

Various materials have different heat conduction properties, metal is better, glass, feathers, fur, etc. are poor.

- Convection is the process of relying on the flow of liquid or gas to transfer the internal energy from the higher temperature part to the lower part. Convection is the main way of heat transfer between liquid and gas, and the convection of gas is more obvious than that of liquid.

- Heat radiation is a process in which an object directly emits energy and transmits it to other objects without relying on the medium. Thermal radiation is the main way to transfer energy over long distances. For example, solar energy is transmitted to the earth through space in the form of thermal radiation.

How Do Insulated Cups Work?

How does a double wall stainless steel cup keeps water hot for 12 hours or icy cold for 24 hours?

As we know from the previous paragraph, there are three ways of heat transmission:

- Radiation

- Convection

- Conduction

The structure of the vacuum insulated cup perfectly prevents the three heat transfer methods. The silver-white surface inside the thermal insulation cup can reflect the radiation of the hot water, the vacuum layer between the double-layer stainless steel walls can block the heat transfer, and the bottle cap that is not easy to transfer heat can prevent the heat convection.

Copper plating of the inner tank can significantly enhance the heat preservation effect. Please refer to this article for details: Insulated Cup: Thermal Insulation Effect of Copper Plating on the Inner Wall

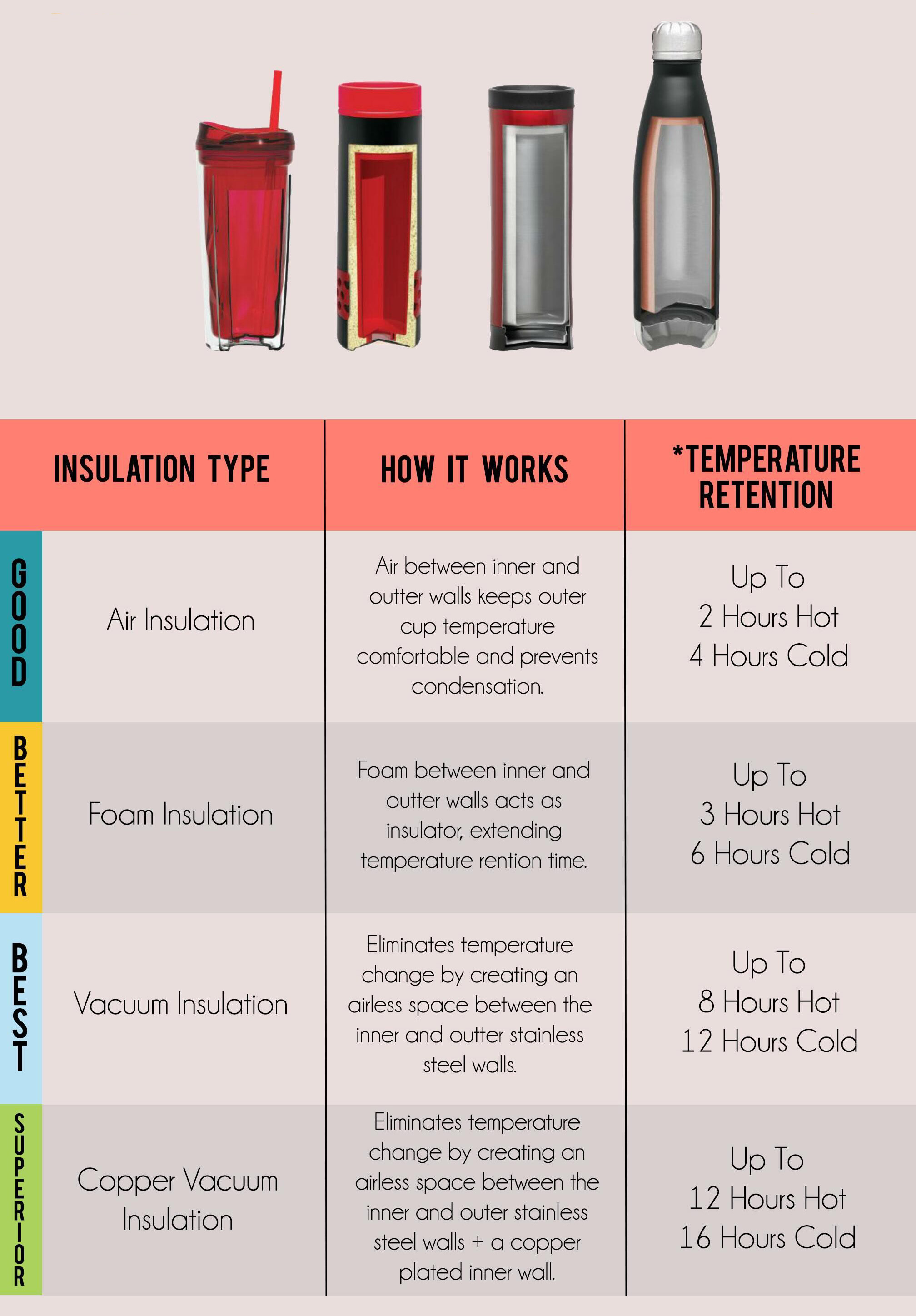

What are the Differences Between Air Insulated Cup, Foam Insulation Cup, Vacuum Insulated Cup, And Copper Plated Vacuum Insulation thermal Cup?

| INSULATION TYPE | HOW IT WORKS | *TEMPERATURE RETENTION | ||

| GOOD | Air Insulation | Air between inner and outer walls keeps outer cup temperature comfortable and prevents condensation. | Up To 2 Hours Hot 4 Hours Cold |

|

| BETTER |

|

Foam between inner and outer walls acts as an insulator, extending temperature retention time. | Up To 3 Hours Hot 6 Hours Cold |

|

| BEST | Vacuum Insulation | Eliminates temperature change by creating an airless space between the inner and outer stainless steel walls. | Up To 8 Hours Hot 12 Hours Cold |

|

| SUPERIOR | Copper Vacuum | Eliminates temperature change by creating an airless space between the inner and outer stainless steel walls + a copper plated inner wall. | Up To 12 Hours Hot 16 Hours Cold |

Insulated stainless steel cup manufacturing video

Vacuum Insulated Stainless Steel Cup Manufacturing Process

Brief description: Stainless steel arrives at the factory in the form of pines and sheets –> Produce outer bottle and inner wall –> Assembly and welding –> Vacuuming –> Decorating.

1. Manufacture Outer Wall

1.1 Pipe cutting: Cut raw material – stainless steel pipe – to the appropriate length.

1.2 Expansion

There are basically two different ways to make stainless steel into the shape of a bottle: water expansion and stretching.

Water Expansion: Stainless steel pipes are raw material for this method. First, stainless steel pipe is put on the water expansion machine. The pipe swells into a bottle shape under the huge pressure of the water. With this method, the bottle formed is with no bottom, so a round stainless steel plate will be welded onto it to form a complete bottle.

Stretch: Stainless steel sheets are raw material for this method. First, the stainless steel sheets are cut into round plates at appropriate size, and then we use a punch press to stretch the stainless steel plate into a cylinder with a bottom.

The outer bottle can be formed by any of these two methods. Water expansion is more popular.

1.3 Separating: If using water expansion process to form outer bottle, then separating process is a must.

1.4 Shaping: Use a large press and follow the “Bottle Shaping Guide” to ensure that the pits, size and shape of the outer bottle meet the requirements.

1.5 Necking: Use a machine to squeeze the upside of the bottle to be a bottle neck.

1.6 Thread Rolling/Making: Threads are made with a special threading machine. Ensure that the thread meets requirements.

1.7 Cleaning: Removes lubricating oil and dust during molding.

1.8 Inspection

2. Manufacture Inner Wall

2.1 Pipe cutting: Cut raw material – stainless steel pipe – to the appropriate length.

2.2 Expansion. Water expansion or stretch. The inner bottle can be formed by any of these two methods. Water expansion is more popular.

2.3 Separating

2.4 Shaping

2.5 Necking

2.6 Thread Rolling/Making (Normally if outer bottle is designed with thread, there’s no thread on inner bottle)

2.7 Cleaning

2.8 Inspection

3. Assembly (Bottle Mouth Matching)

Assemble the inner bottle and the outer bottle together by pressing machine.

4. Cup Bottom Assembly

Assemble the bottom to the bottle by pressing machine.

5. Assembly (Cup Mouth Welding)

Weld the inner bottle and outer bottle together to prepare for vacuum insulation. Ensure smoothness, no bumps or solder joints.

6. Assembly (Cup Bottom Welding)

Weld the outer bottle and the bottle bottom to prepare for vacuum insulation. Ensure smoothness, no bumps or solder joints.

7. Leaking Test

Check whether inner bottle and outer bottle were well welded.

8. Vacuuming

Vacuuming with a vacuum machine.

9. Temperature Test / Insulation Test

Blow hot air into each bottle. If the outside of the bottle is kept cool, it means that the heat from the hot air will not be diverted and the bottle is vacuum insulated. On the contrary, if the bottle gets hot, there is a problem with vacuum insulation.

10. Electrolysis Polishing

Through the interaction of current and electrolyte to improve the micro-geometry of the metal surface, reduce the surface roughness of the metal, so as to achieve the purpose of bright and smooth surface of the stainless steel bottle. Surface of inner bottle to be bright and even, no watermark, yellow dot.

11. Mechanical Polishing

Polish the surface of outer bottle to ensure it is smooth and bottle mouth is smooth and bright. There must be no obvious drawing, scratching, black wire and pits.

12. Cleaning

Clean the bottle and dry it. Make the bottle ready for external coating / decorating.

13. Temperature Test / Insulation Test

Blow hot air into each bottle. If the outside of the bottle is kept cool, it means that the heat from the hot air will not be diverted and the bottle is vacuum insulated. On the contrary, if the bottle gets hot, there is a problem with vacuum insulation.

14. External Coating(surface decorating)

The bottle is now ready for external coating –powder coating or spray painting. KingStar is capable of doing both spray printing and powder coating process.

15. Pattern and Logo Printing

Print the pattern design and logo on the bottle with various techniques – screen printing, thermal transfer printing, water transfer printing, laser etching and so on.

16. Temperature Test / Insulation Test

Blow hot air into each bottle. If the outside of the bottle is kept cool, it means that the heat from the hot air will not be diverted and the bottle is vacuum insulated. On the contrary, if the bottle gets hot, there is a problem with vacuum insulation.

17. Packing

After inspect each bottle, including visual inspection and lid leak test, the bottle is place in a separate bag for packaging.

Click and read more about stainless steel insulated cup manufacturing: Manufacturing Process of Vacuum Insulated Stainless Steel Cups