One of the most concerned topics of stainless steel water bottle buyers and vacuum flask enthusiasts is the detailed list of the manufacturing cost of the stainless steel water bottles. Knowing the manufacturing cost of stainless steel water bottles in detail will help reduce procurement costs and optimize the plan for customizing stainless steel water bottles, so that you can purchase the best quality and most suitable stainless steel water bottles within your budget.

This article will give a detailed introduction to the manufacturing cost of stainless steel water bottles.

Types of Stainless Steel Water Bottles

There are different types of water bottles in the market, including stainless steel water bottles.

Classified according to the grades of stainless steel materials:

316 stainless steel water bottles (medical grade stainless steel)

304 stainless steel water bottles (food grade 18/8 stainless steel)

201 stainless steel water bottles (not food grade, phasing out from market)

Classification according to the number of bottle walls

Classification on walls, the stainless steel water bottle has 3 different types:

- single wall stainless steel water bottles

- double walls stainless steel water bottles

- triple walls stainless steel water bottles

Both of them are mainly made by kitchen food grade stainless steel 18/8 (SUS304) in terms of their body parts, and the lids/caps are usually made by plastic or stainless steel with silicone sealing gaskets.

With double-walled stainless steel structure, this water bottle can keep water hot for 12 hours or ice cold for up to 24 hours. Currently, the double wall stainless steel water bottle is gaining increasing popularity in the global markets.

Triple walls insulated stainless steel keeps drinks cold for 30 hours & hot for 15 hours. The well-known triple-walled vacuum flask on the market such as Corkcicle. However, due to the bloated appearance of the three-walled vacuum flask, it is not easy to carry and is not very popular with consumers. This article will skip the manufacturing cost of the three-layer vacuum flask.

According to the usage scenario of the water bottle:

- Sports stainless steel water bottle

- Car water bottles

- Outdoor bottles

- Indoor water bottles

According to the types of beverages that are suitable, SS water bottles can also be divided into SS coffee bottles, SS soda bottles, SS milk bottles, stainless steel tea bottles and so on.

How Do Vacuum Insulated Stainless Steel Water Bottles Work

How does a double wall stainless steel water bottle keep water hot for 12 hours or icy cold for 24 hours?

There are three ways of heat transmission:

- Radiation

- Convection

- Transmission

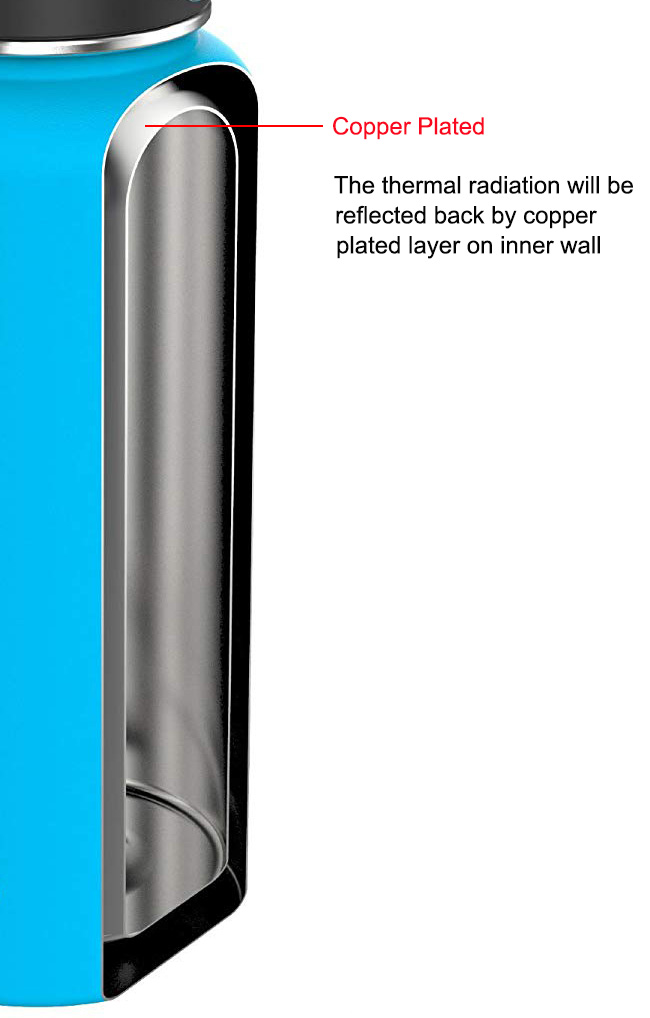

The silver-white surface inside the thermal insulation cup can reflect the radiation of the hot water, the vacuum layer between the double-layer stainless steel walls can block the heat transfer, and the bottle cap that is not easy to transfer heat can prevent the heat convection.

Copper plating of the inner tank can significantly enhance the heat preservation effect. Please refer to this article for details: Insulated Water Bottle: Thermal Insulation Effect of Copper Plating on the Inner Wall

Wide Mouth Bottle 32oz

$3.98-$4.83

Sport Water Bottle 18 oz

$3.12-$3.46

Cola Shaped Bottle 17 oz

$3.05-$3.26

How Much Does It Cost to Manufacture Stainless Steel Water Bottles?

If you want to launch a custom design stainless steel water bottle project, you need to know how much it will cost you for manufacturing and customizing a single bottle. Besides, it is also a must to know what will affect the entire cost.

In this situation, you are in the right place here as we KingStar, the leading custom water bottle manufacturer, can help you to find out the important things you should know about the prices/costs of Stainless Steel Water Bottle Manufacturing.

The cost of manufacturing stainless steel water bottles can be varied, which mainly depends on the custom design requirement and the order quantities.

There are some basic information about the price of stainless steel bottles that you definitely need to know. For example, the product cost will occur when you set up the project even when the production has not been launched yet; the material not only affects the quality of the stainless steel water bottle but also is the main cost of your customized products; the order quantities also occupies a large part of the whole cost, especially affecting the shipment cost for your water bottle products.

The main factors affecting the manufacturing cost of stainless steel water bottles:

- The cost of material

- Different order quantity

- The timing of your order

- Manufacturing process-water expanding process and stretching process

- Manufacturing process-copper plating process

- Manufacturing process-overall

- The cost of using surface decoration

- Private Label-custom logo technology

- Caps, brushes, boots and other Accessories

- Packaging cost

- Labor cost

- Logistics cost

To understand more, let’s take a look at each of them that affects the pricing of vacuum insulated stainless steel water bottles.

The Cost of Material

List of main materials for stainless steel water bottles:

- Bottle body: stainless steel18/8 (SUS304), SUS201; SS316; titanium

Most of the water bottles and other kitchen drinkware brands are using stainless steel 18/8 (also named SUS304), a BPA-free material that has been widely used in products of different fields with good rust-resistance and premium food grade, and with BPA-free, non-toxic, reusable, recycle and environment-friendly features.

Material cost: titanium > stainless steel 316 > stainless steel 304(SS 18/8) > stainless steel 201

Main features: 316 stainless steel is medical grade, 304 stainless steel is food grade, and 201 stainless steel is harmful to the human body. Water cups using 21 stainless steel cannot pass the FDA test.

Read more about stainless steel 316, 304 and 201:

- Bottle cap/lid: plastic (PP, Tritan, AS), stainless steel

Most of the bottle caps/lids are made by polypropylene plastic material, a food grade material that is durable, recycle, BPA free, and is widely used in tableware products.

Now we can see that some stainless steel water bottle brands or manufacturers have started to develop the bottle cap/lid with stainless steel or Tritan material to present high-end quality of the product and improve the corporate recognition.

- Seal gasket: solid silicone, liquid silicone

We need to know that the bottle must have a soft seal gasket to prevent water leaking issues. The gasket can be made with two types of silicone material (both are food grade, BPA free and reusable). And most of the stainless steel water bottles in the market are using solid silicone to save costs.

The cost of your material is often valued in per g. The cost of main materials for stainless steel water bottle are:

- 18/8 Stainless steel costs $0.005 / g

- 316 Stainless steel costs $0.006 / g

- 201 Stainless steel costs $0.0045 / g

- polypropylene costs $0.002 / g

- AS costs $0.0025 / g

- TRITAN costs $0.005 / g

- Silicone costs $0.003 / g

It’s important to know that there would have material waste in production, which means your order quantities should be slightly larger than that required by customers, and you have to reduce the average waste of raw material for each product by improving the manufacturing process so as to obtain more profits.

Different Order Quantities

The order quantities would have big impact on the manufacturing cost, affecting greatly the cost of each stainless steel water bottle.

Generally, different quantities of the order will lead to different discounts of your products. See the figures below:

- MOQ 3000PCS

- 10000PCS (1% cost down)

- 30000PCS (2% cost down)

- 50000PCS (2.5% cost down)

- 100000PCS (3% cost down)

- 500000PCS(3.5% cost down)

As you can see, the bigger volume of your water bottle order quantities, the more discount you can obtain.

KingStar supports startups and small businesses. The first order can be less than 3000pcs. But if your purchase quantity is less than 3000pcs, the unit price will rise by at least 10%. The order quantity of less than 3000pcs will produce a lot of waste in each production process.

Also you can save the average shipment cost of a product a lot with larger quantities. For a standard size 17oz/500ml stainless steel water bottle, you can choose shipment as follows;

- less then 100pcs: air shipment, fast but very expensive

- 100~3000pcs: sea shipment LCL slow and expensive

- 16000pcs: sea shipment FCL 20″ GP container, slow and cheap

- 32000pcs: sea shipment FCL 40″ GP container, slow and very cheap

The Timing of Your Order

When your stainless steel bottle order quantities are small, and the customer wants them urgently, the price would be higher than usual.

When your order is one time order and is with urgent time, the price would be higher than usual.

Manufacturing process-Water expanding process and stretching process

The water cup using the stretching process is more beautiful and has no seams. But the cost is higher. Take the 500ml tumbler cup as an example, the unit price of the finished product using the stretching process is USD0.6 higher than the unit price of the finished product using the water expanding process.

Manufacturing process-copper plating process

Copper plating on the outer layer of the inner tank: USD 0.2/ unit

Manufacturing process-Overall

Non-circular stainless steel cups with peculiar shapes are more expensive to manufacture. For details, see how to design a thermos cup.

The collapsible stainless steel bottles have higher requirements for sealing, more thread processes, so the manufacturing costs is higher.

The smart module of the smart stainless steel water bottle contains complex electronic design, electronic components, battery, Bluetooth, etc., which are usually more expensive to manufacture.

Water bottles with sterilization function, such as Larq, have high costs for UV lamps and electronic modules, and the overall manufacturing cost is higher.

The cost of a special customized water cup project needs to be specifically estimated according to the specific design.

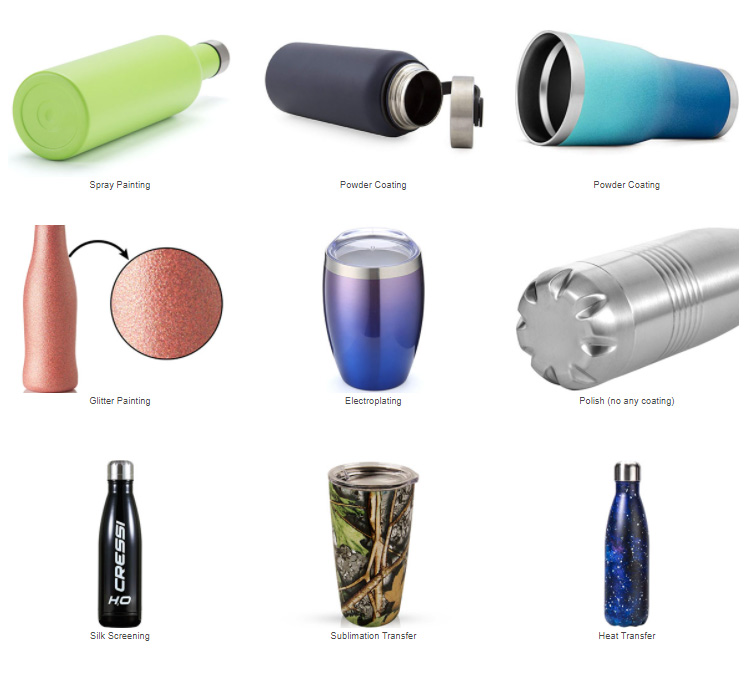

The Cost of Different Surface Decoration:

We can do different custom surface treatments for your stainless steel water bottles both inside and outside, depending on your design requirements.

There’s no plate charge cost when you only want to apply different Pantone colors with spray painting, powder coating or UV plating.

The plate charge cost occurs when you want to have different graphic decorations for your custom design water bottle with different techniques, such as logo printing, logo embossing, water transfer, heat transfer, spray transfer and air transfer printing etc.

The plate charge cost ranges from 50USD to 600USD, and the sample lead time takes 1-2 weeks.

Here we have cost lists for different surface treatments of stainless steel water bottles:

- Spray painting: 0.15USD/each color

- Powder coating: 0.40USD/each color

- Heat transfer printing: 0.15USD(painting base) + 0.10USD (printing)

- Sublimation transfer printing: 0.60USD + plate fee USD600

- Water transfer printing: 0.40USD

Click here and you can find out different surface decoration for custom water bottle decoration

Private Label-custom logo technology

Silk Screen logo(single color): 0.03USD

Silk Screen logo(two colors): 0.07USD

Laser engraving logo: 0.05-1.15USD, depends on the size of logo

Embossing/debossing logo: Need to build new tooling to achieve. The pricing depends on logo size and how complex of the logo.

Emblem logo: 0.3USD – 3 USD. It depends on badge material and size.

3D printing logo: 0.1USD-0.2USD. It depends on how complex of the logos and the size of logo.

Caps, brushes, paracords, silicone boots and Other Accessories

The number of bottle lids, the complexity of the bottle lids, and the number of other accessories all have a greater impact on the water cup.

Many water cups on the market are equipped with 2 lids. Some water cups even have three lids. Such as Hydro Cell, Simple Modern, etc.

Cap cost: 0.5USD-1.5USD

The cost of different caps is different, and the cost of different accessories is also different. Specific calculations are required for specific items. They are not listed in detail here.

Packaging Methods

Packaging cost: For some special products that need a custom design packaging, this will surely result in additional cost.

Square white box: 0.1USD

Square color box: 0.2USD

Cylinder color box: 0.5USD

Display box: 0.4USD-0.5USD it depends on the design.

Labor Cost

Although China is known as the world’s factory, it has abundant human resources. However, in recent years, labor costs have been rising year by year. The labor cost accounts for an increasing proportion of the production cost of the stainless steel water bottles.

Logistics cost

The cost of air shipment, sea shipment and express shipment are different per KG. Ocean freight has been affected by COVID-19 and has increased significantly. Both train transportation and truck transportation are good choices for access to the European continent. We are working with DHL/FEDEX/UPS and other forwarders to have competitive cost for your shipment.

Insulated Metal Tumbler 20 oz

$2.15-$3.16

Insulated Tumbler 30 oz

$2.59-$3.90

Skinny Blank Tumbler 20 oz

$2.35-$3.26

Tumbler with Straw 18 oz

$3.25-$3.95

Insulated Rambler Mug 14 oz

$5.51-$6.31

Vacuum Insulated Stainless Steel Bottle Tumbler Manufacturing Process

Brief description: Stainless steel arrives at the factory in the form of pines and sheets –> Produce outer bottle and inner bottle –> Assembly and welding –> Vacuuming –> Decorating.

1. Manufacture Outer Bottle

1.1 Pipe cutting: Cut raw material – stainless steel pipe – to the appropriate length.

1.2 Expansion

There are basically two different ways to make stainless steel into the shape of a bottle: water expansion and stretching.

Water Expansion: Stainless steel pipes are raw material for this method. First, stainless steel pipe is put on the water expansion machine. The pipe swells into a bottle shape under the huge pressure of the water. With this method, the bottle formed is with no bottom, so a round stainless steel plate will be welded onto it to form a complete bottle.

Stretch: Stainless steel sheets are raw material for this method. First, the stainless steel sheets are cut into round plates at appropriate size, and then we use a punch press to stretch the stainless steel plate into a cylinder with a bottom.

The outer bottle can be formed by any of these two methods. Water expansion is more popular.

1.3 Separating: If using water expansion process to form outer bottle, then separating process is a must.

1.4 Shaping: Use a large press and follow the “Bottle Shaping Guide” to ensure that the pits, size and shape of the outer bottle meet the requirements.

1.5 Necking: Use a machine to squeeze the upside of the bottle to be a bottle neck.

1.6 Thread Rolling/Making: Threads are made with a special threading machine. Ensure that the thread meets requirements.

1.7 Cleaning: Removes lubricating oil and dust during molding.

1.8 Inspection

2. Manufacture Inner Bottle

2.1 Pipe cutting: Cut raw material – stainless steel pipe – to the appropriate length.

2.2 Expansion. Water expansion or stretch. The inner bottle can be formed by any of these two methods. Water expansion is more popular.

2.3 Separating

2.4 Shaping

2.5 Necking

2.6 Thread Rolling/Making (Normally if outer bottle is designed with thread, there’s no thread on inner bottle)

2.7 Cleaning

2.8 Inspection

3. Assembly (Bottle Mouth Matching)

Assemble the inner bottle and the outer bottle together by pressing machine.

4. Bottle Bottom Assembly

Assemble the bottom to the bottle by pressing machine.

5. Assembly (Bottle Mouth Welding)

Weld the inner bottle and outer bottle together to prepare for vacuum insulation. Ensure smoothness, no bumps or solder joints.

6. Assembly (Bottle Bottom Welding)

Weld the outer bottle and the bottle bottom to prepare for vacuum insulation. Ensure smoothness, no bumps or solder joints.

7. Leaking Test

Check whether inner bottle and outer bottle were well welded.

8. Vacuuming

Vacuuming with a vacuum machine.

9. Temperature Test / Insulation Test

Blow hot air into each bottle. If the outside of the bottle is kept cool, it means that the heat from the hot air will not be diverted and the bottle is vacuum insulated. On the contrary, if the bottle gets hot, there is a problem with vacuum insulation.

10. Electrolysis Polishing

Through the interaction of current and electrolyte to improve the micro-geometry of the metal surface, reduce the surface roughness of the metal, so as to achieve the purpose of bright and smooth surface of the stainless steel bottle. Surface of inner bottle to be bright and even, no watermark, yellow dot.

11. Mechanical Polishing

Polish the surface of outer bottle to ensure it is smooth and bottle mouth is smooth and bright. There must be no obvious drawing, scratching, black wire and pits.

12. Cleaning

Clean the bottle and dry it. Make the bottle ready for external coating / decorating.

13. Temperature Test / Insulation Test

Blow hot air into each bottle. If the outside of the bottle is kept cool, it means that the heat from the hot air will not be diverted and the bottle is vacuum insulated. On the contrary, if the bottle gets hot, there is a problem with vacuum insulation.

14. External Coating(surface decorating)

The bottle is now ready for external coating –powder coating or spray painting. KingStar is capable of doing both spray printing and powder coating process.

15. Pattern and Logo Printing

Print the pattern design and logo on the bottle with various techniques – screen printing, thermal transfer printing, water transfer printing, laser etching and so on.

16. Temperature Test / Insulation Test

Blow hot air into each bottle. If the outside of the bottle is kept cool, it means that the heat from the hot air will not be diverted and the bottle is vacuum insulated. On the contrary, if the bottle gets hot, there is a problem with vacuum insulation.

17. Packing

After inspect each bottle, including visual inspection and lid leak test, the bottle is place in a separate bag for packaging.