Laser engraving has become an increasingly popular way to personalize everyday items, and Yeti cups are a great choice for customization. These durable and insulated cups are known for their quality, making them an ideal choice for adding a touch of uniqueness. Whether it’s for your own use or to give as a unique gift to friends, getting an engraved Yeti cup or bottle enables you to showcase your creativity and individuality. In this article, we’ll walk you through getting started with laser engraving on your Yeti cups or wholesale stainless steel water bottles, giving them a fresh and personalized touch!

1. Which Yeti cup or bottle is suitable for laser engraving?

Actually, any stainless steel Yeti cup or bottle is suitable for laser engraving. Yeti’s stainless steel products are commonly used for customization through laser engraving due to their durable and smooth surfaces. Here we’ll list some popular models of Yeti cups or bottles for your reference:

Yeti Rambler Tumbler

Sizes: Available in various sizes, including 20 oz and 30 oz.

Features: Double-wall vacuum insulation, no sweat design to keep your hands dry, durable stainless steel construction.

Example Engraving: You can personalize it with a name, logo, or custom design. For instance, you could engrave a company logo for corporate gifts or a special message for a gift.

Yeti Rambler Bottle

Sizes: Available in different sizes, such as 18 oz, 26 oz, and 36 oz.

Features: Durable stainless steel, TripleHaul™ Cap for easy carrying, insulated to keep beverages hot or cold.

Example Engraving: Engrave motivational quotes, outdoor adventure designs, or even a monogram for a personalized touch.

Yeti Rambler Lowball

Size: Comes in a 10 oz size.

Features: Ideal for hot or cold beverages, no sweat design, and made with stainless steel.

Example Engraving: Engrave initials or a short message for a unique gift, or consider humorous quotes for a fun twist.

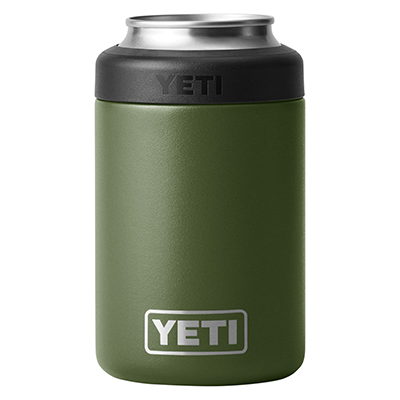

Yeti Rambler Closter

Features: Stainless steel construction, no sweat design, and a gasket to keep your canned or bottled beverage securely in place.

Example Engraving: Engrave a name or favorite saying to create a customized beverage holder for personal use or as a gift.

Yeti Rambler Wine Tumbler

Wholesale 220z tumbler rambler, unit price 3.55

Features: Stainless steel wine tumbler with MagSlider Lid to prevent spills, double-wall insulation for temperature retention.

Example Engraving: Personalize with a monogram, date, or a design related to wine appreciation.

2. What other materials you need to laser engrave Yeti cups or bottles?

Yeti cups or bottles we mentioned above are must for later process. Here we list some items you need for your safe and smooth laser engraving:

- Laser Engraving Machine: The laser engraving machine is the primary tool that etches your design onto the stainless steel surface. It emits a focused laser beam that removes a thin layer of the material to create the engraved pattern. Modern laser engraving machines offer various settings that allow you to control the depth, speed, and intensity of the engraving.

- Vector Graphics Software (e.g., Adobe Illustrator, CorelDRAW): Vector graphics software is essential for creating the design you want to engrave. Unlike raster images, vector graphics are made of paths defined by mathematical equations, allowing for scalability without loss of quality. This is crucial for producing clean and sharp engravings. Software like Adobe Illustrator or CorelDRAW enables you to design intricate and precise artwork.

- Safety Goggles: Safety goggles are a must when working with laser engraving machines. The laser beam used in engraving can emit intense light that could potentially harm your eyes. Safety goggles designed for laser work offer the necessary protection against these powerful beams.

- Ventilation (if working indoors): Engraving stainless steel can produce fumes and particles that may not be safe to inhale. Proper ventilation helps disperse these fumes, creating a safer working environment. If you’re working indoors, having good ventilation is essential to maintain air quality.

- Personal Protective Equipment (PPE) Including Gloves: Personal protective equipment, such as gloves, helps ensure your safety during the engraving process. Gloves protect your hands from accidental burns or exposure to chemicals. Depending on the specific setup and materials you’re using, wearing appropriate PPE helps minimize potential risks.

Click and read more: Laser Engraving Machine to Mark Black Characters on Stainless Steel Tumbler Cup

3. How to laser engrave Yeti cups or bottles step by step?

Once everything prepared, let’s start this laser engraving journey!

Step 1: Choose a Yeti Cup or Bottle

Select a Yeti cup or bottle that you want to engrave. Make sure it’s clean and free from any dirt, dust, or residue.

Step 2: Measure the Engraving Space

Use calipers or a measuring tool to accurately measure the dimensions of the area where you plan to engrave your design. This measurement will help you create a design that fits perfectly.

Step 3: Set Up the Laser Engraving Machine

Place your laser engraving machine in a well-ventilated and safe workspace. Ensure that the machine is properly connected to a power source and that all safety precautions are in place.

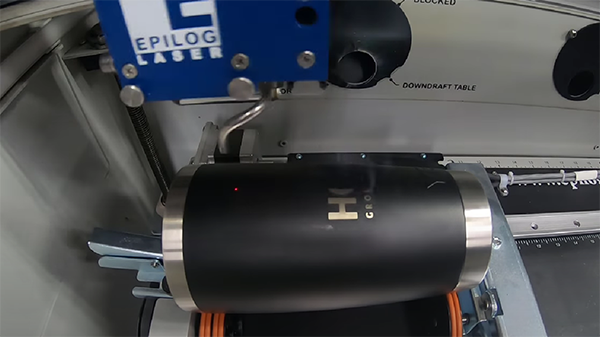

Step 4: Attach the Risers and Rotary Attachment

If you’re using a rotary attachment to engrave cylindrical objects like cups or bottles, attach it to the engraving machine as per the manufacturer’s instructions. This attachment allows the cup or bottle to rotate as it’s being engraved.

Step 5: Design the Pattern or Logo

Using graphic design software, create the pattern or logo you want to engrave. Make sure it’s appropriately sized to fit within the measurements you took in Step 2. Convert your design into a format compatible with the laser engraving software (e.g. AI).

Step 6: Line Up the Laser Engraving Machine

Position the Yeti cup or bottle in the rotary attachment, ensuring it’s securely held and won’t wobble during engraving. Make sure the area you want to engrave is aligned with the laser’s focal point. You might need to adjust the risers to achieve the correct height.

Step 7: Start Engraving

Load your design into the laser engraving software and set the engraving parameters, including power, speed, and resolution. Perform a test engraving on a scrap piece of material if possible to ensure the settings are correct. Once you’re confident in the settings, start the engraving process. Monitor the engraving process to ensure everything is proceeding as expectations.

4. What are safety precautions for laser engraving Yeti cups or bottles?

As we engage in the process of laser engraving on various objects, it is imperative that we prioritize the safety and well-being of all personnel involved. Laser engraving machines are powerful tools that require careful handling to ensure a secure working environment. In line with this, we strongly emphasize the following safety precautions, particularly the use of protective equipment and goggles:

- Wear Appropriate Protective Equipment: When operating the laser engraving machine, it is mandatory for all personnel to wear the appropriate protective equipment. This includes safety goggles designed to shield your eyes from the intense laser light. These goggles are specially crafted to filter out harmful wavelengths and ensure your eyes are safeguarded from potential hazards.

- Use Gloves and Other Protective Gear: Depending on the materials being engraved, gloves and other protective gear may be necessary to shield your hands and skin from potential heat or splinter hazards. Always refer to the material safety data sheets and manufacturer guidelines to determine the proper protective gear required for each engraving task.

- Ensure Proper Fit and Function: Ensure that all protective equipment fits properly and is in good working condition. Ill-fitting goggles or damaged gloves can compromise their effectiveness and your safety.

- Adhere to Laser Engraving Machine Safety Guidelines: In addition to wearing protective equipment, follow all safety guidelines provided by the laser engraving machine manufacturer. Familiarize yourself with emergency shut-off procedures and any other safety measures outlined in the user manual.

- Provide Training: Ensure that all personnel who operate the laser engraving machine receive proper training on its safe usage, including the correct way to wear protective equipment. Regular training sessions can help reinforce the importance of safety protocols.

5. Conclusion

When venturing into the realm of personalized water bottles, partnering with an experienced ODM/OEM drinkware manufacturer like KingStar proves to be the most prudent choice. Not only does KingStar deliver top-notch, high-quality water bottles, but we also offer an array of customization services. With the ability to engage their skilled engineer team, KingStar goes beyond mere production by transforming your design concepts into tangible reality using our cutting-edge equipment and unwavering professional service. This holistic approach ensures that your personalized water bottle journey is marked by exceptional quality, innovative design realization, and a seamless collaboration that culminates in a truly unique and remarkable end product. If you want more information, feel free to contact us!