Contents

- What is Your Expertise and Range of Products?

- Can You Handle Small to Large Order Quantities?

- What Customization Options Do You Offer?

- What is Your Design and Development Process?

- What is Your Quality Control Process?

- What is Your Lead Time?

- What is Your Pricing Structure?

- How Do You Handle Logistics and Shipping?

- What is Your Environmental Commitment?

The promotional drinkware industry is constantly changing where brands and businesses seek to make a lasting impression. Custom-designed drinkware offers a unique opportunity to improve brand visibility, engage customers, and reinforce brand messaging. Outsourcing the manufacturing process can be a strategic decision that unlocks efficiency, cost-effectiveness, and access to specialized expertise. However, selecting the right manufacturing partner is crucial for achieving your desired outcomes.

With countless manufacturers competing for your business, it’s essential to approach the decision-making process with a critical eye. Asking the right questions upfront can save you time, money, and headaches down the line. As a leading drinkware manufacturer, we are writing this article to delve into nine critical questions to guide you in selecting the ideal partner for your custom drinkware project and corporate gifts. Whether you’re looking for stainless steel tumblers, insulated coffee cups, eco-friendly water bottles, or any other drinkware item, these insights will empower you to make informed choices.

By carefully evaluating a manufacturer’s capabilities, experience, and commitment to quality, you can confidently entrust your brand’s reputation to a partner who will deliver exceptional products that exceed your expectations.

1. What is Your Expertise and Range of Products?

Understanding a manufacturer’s core competencies is fundamental to ensuring they can deliver the specific drinkware you envision. A company with a deep-rooted expertise in your desired product category, such as KingStar, will likely possess superior knowledge of materials, production techniques, and industry trends.

For instance, if you’re focused on high-end stainless steel tumblers, look for a manufacturer with a proven track record in producing vacuum-insulated products. They should be well-versed in different grades of stainless steel, insulation technologies, and the latest advancements in tumbler design.

Similarly, if you’re targeting eco-conscious consumers with reusable water bottles, a manufacturer specializing in sustainable materials like bamboo, glass, or recycled Aluminum would be an ideal fit. Their experience in sourcing eco-friendly materials and implementing sustainable production processes is crucial.

A comprehensive product range is another essential factor. A manufacturer offering a diverse selection of drinkware items can accommodate various project requirements and potentially become a long-term partner. Consider whether they specialize in specific product categories (e.g., stainless steel tumblers, insulated coffee mugs, vacuum flasks) or offer a broader range that includes items like travel mugs, beer growlers, and food containers.

By carefully assessing a manufacturer’s expertise and product offerings, you can select a partner capable of delivering the exceptional drinkware that aligns with your brand’s identity and target audience.

2. Can You Handle Small to Large Order Quantities?

Flexibility in order quantity is crucial for businesses experiencing fluctuating demand or those entering the promotional drinkware market for the first time. A reliable manufacturer should be able to accommodate both small initial orders and large-scale production runs without compromising quality or lead times.

Small order quantities are essential for testing product viability, launching new product lines, or fulfilling niche market demands. A manufacturer that can handle small orders efficiently demonstrates a commitment to customer satisfaction and a willingness to support businesses at various stages of growth.

On the other hand, large order quantities are often necessary for major promotional campaigns, corporate giveaways, or establishing a strong market presence. A manufacturer with the capacity to handle high-volume production while maintaining quality standards is essential for meeting tight deadlines and ensuring consistent product delivery.

Inquire about the manufacturer’s minimum order quantity (MOQ) requirements and their ability to scale production to meet your specific needs. A partner who can adapt to your changing order volumes can be a valuable asset to your business.

3. What Customization Options Do You Offer?

Customization is the cornerstone of creating drinkware that truly aligns with your brand and target audience. A comprehensive range of customization options allows you to bring your unique design to life.

Material Selection: The choice of material significantly impacts the look, feel, and functionality of your drinkware. Inquire about the variety of materials available, such as:

- Stainless steel: Known for its durability, insulation properties, and sleek appearance. Consider different grades (18/8, 304) and finishes (matte, glossy, powder coating) to achieve your desired aesthetic.

- Aluminium: Lightweight and often used for budget-friendly options. Explore color coatings and finishes to enhance its visual appeal.

- Glass: Offers a classic, elegant look and is ideal for showcasing product designs. Consider double-wall insulation for added functionality.

- Plastic: Versatile and affordable, but consider factors like BPA-free materials and durability.

Color Options: A wide color palette is essential for creating visually appealing drinkware. Ask about the available color options for both the exterior and interior of the product. Consider whether they offer standard color choices or can match custom color requests.

Finishes: The finish of your drinkware can significantly impact its overall appearance and feel. Explore options such as:

- Matte: Provides a modern, understated look.

- Glossy: Offers a sleek, polished finish.

- Powder coating: Durable and available in a wide range of colors and textures.

- Metal finishes: Brushed, satin, or mirror finishes for a premium look.

Imprint Methods: The chosen imprint method will determine the quality and longevity of your design. Discuss the following options with the manufacturer:

- Screen printing: Ideal for large, vibrant designs.

- Laser engraving: Creates a permanent, high-quality imprint, especially suitable for stainless steel.

- Pad printing: Suitable for intricate designs and curved surfaces.

- Digital printing: Offers high-resolution images and full-color capabilities.

Shapes and Sizes: The shape and size of your drinkware should complement its intended use and target audience. Inquire about the available options, such as:

- Tumbler shapes: Straight, tapered, or curved.

- Bottle shapes: Sleek, athletic, or classic.

- Lid styles: Flip-top, screw-on, slider, or sports cap.

4. What is Your Design and Development Process?

A well-defined design and development process is essential for transforming your vision into a tangible product. A collaborative partnership between you and the manufacturer is crucial for achieving optimal results.

Design Concept Refinement: A skilled design team should be able to take your initial ideas and transform them into practical and visually appealing designs. Look for a manufacturer that offers:

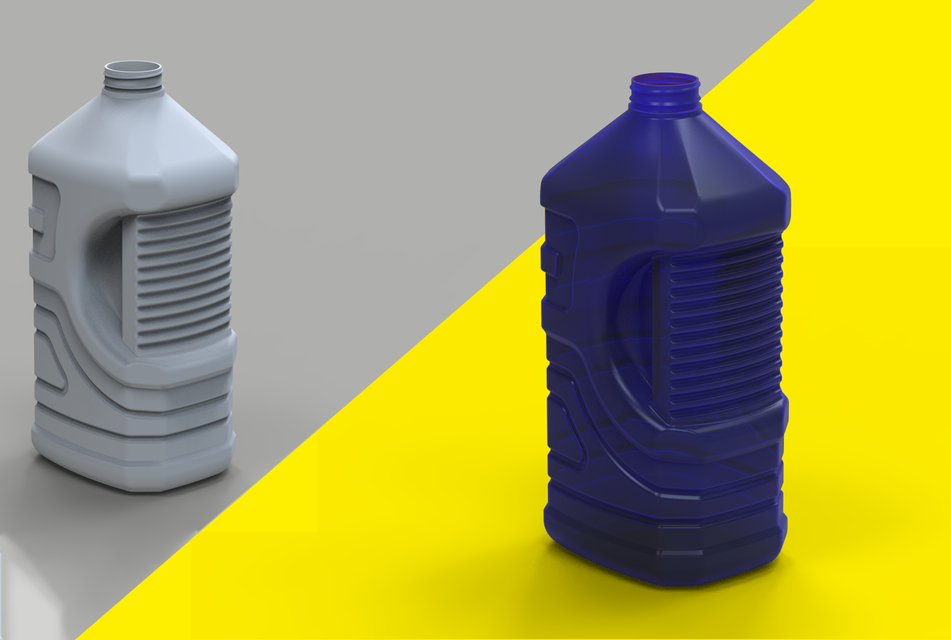

- Concept visualization: The ability to create 2D and 3D renderings to help you visualize the final product.

- Design feedback: Constructive input and suggestions to improve your design.

- Trend analysis: Knowledge of the latest drinkware trends to ensure your product remains relevant.

Prototyping: A physical prototype is invaluable for assessing product functionality, aesthetics, and overall fit. A reputable manufacturer will offer:

- Rapid prototyping: Quick turnaround times for initial prototypes.

- Material selection: Ability to create prototypes using various materials to test different options.

- Functionality testing: Rigorous testing to ensure the product meets performance expectations.

Quality Assurance: A thorough design and development process includes rigorous quality control measures. Inquire about:

- Design review: Detailed examination of the design for potential issues.

- Prototype testing: Functional and aesthetic testing to identify areas for improvement.

- Material testing: Ensuring materials meet safety and performance standards.

By partnering with a manufacturer that has a robust design and development process, you can be confident that your custom drinkware will meet your expectations and exceed your customers’ demands.

3D Printed Water Bottle Prototype

5. What is Your Quality Control Process?

A robust quality control process is essential for ensuring that your custom drinkware meets the highest standards. As mentioned, it safeguards your brand reputation and customer satisfaction. Inquire about the manufacturer’s quality control measures, including:

- Incoming Material Inspection: Verifying that raw materials meet specified quality standards. This includes checking for defects, impurities, and compliance with safety regulations.

- In-Process Inspection: Monitoring production processes to identify and rectify any issues early on. This involves regular checks on dimensions, finishes, imprints, and overall product integrity.

- Functional Testing: Assessing product performance to ensure it meets intended use. This might include leak tests, insulation performance tests, and durability assessments.

- Visual Inspection: Examining products for aesthetic flaws such as scratches, blemishes, or inconsistencies in color or finish.

- Packaging Inspection: Ensuring products are properly packaged to prevent damage during shipping.

- Certifications and Compliance: Verifying adherence to industry standards and regulations, such as FDA, LFGB, or BPA-free certifications.

- Statistical Process Control (SPC): Utilizing data analysis to identify trends and prevent quality issues.

A transparent and detailed explanation of the quality control process, along with supporting documentation like inspection reports or certifications, can provide you with confidence in the manufacturer’s commitment to excellence.

6. What is Your Lead Time?

The lead time directly impacts your ability to meet campaign deadlines and customer expectations. A reliable manufacturer will provide clear and accurate lead time estimates.

Several factors influence lead time, including order quantity, product complexity, customization level, and production capacity. Inquire about the manufacturer’s typical lead times for different order volumes and product types.

Key questions to ask:

- What is the average lead time for a standard product with minimal customization?

- How does order quantity impact lead time?

- What is the lead time for custom-designed products?

- Can you expedite production for urgent orders? If so, what are the additional costs and potential impacts on quality?

- Do you have the capacity to handle peak seasons or unexpected order surges?

Understanding the manufacturer’s production capacity and its ability to meet tight deadlines is essential for effective project planning and management. A partner with a consistent track record of on-time delivery can help you avoid costly delays and maintain customer satisfaction.

7. What is Your Pricing Structure?

Understanding the pricing structure is crucial for budgeting and profit margin calculations. A transparent pricing model fosters trust and allows for accurate cost comparisons.

Essential questions to ask:

- Base price: What is the cost per unit for a standard product without any customizations?

- Customization costs: How are additional costs for customizations calculated? Are there minimum charges or tiered pricing based on complexity?

- Order quantity discounts: Are there volume discounts available for larger orders?

- Setup fees: Are there any setup or tooling costs for new designs or orders?

- Shipping and handling: How are shipping costs calculated? Are there any additional fees for packaging or handling?

- Minimum order quantity (MOQ): Is there a minimum order requirement, and how does it impact pricing?

- Payment terms: What payment options are available (e.g., upfront payment, deposit, net terms)?

Request a detailed price breakdown for a sample order that closely resembles your project to get a clear understanding of the total cost. Compare pricing from multiple manufacturers to identify the best value for your budget.

It’s important to consider not just the initial unit price but also the total cost of ownership, including factors like shipping, customs duties, and potential defects. A lower unit price might not always translate to the best overall value.

8. How Do You Handle Logistics and Shipping?

Efficient logistics and shipping are crucial for timely delivery and customer satisfaction. A reliable manufacturer should have a well-established system in place to handle the transportation of your products.

Key areas to inquire about:

- Shipping Options: Understand the available shipping methods (e.g., ocean freight, air freight, ground transportation) and their associated costs and transit times.

- Packaging: Inquire about the standard packaging materials used and whether custom packaging options are available to protect your products during transit.

- Shipping Documentation: Ask about the necessary shipping documentation (e.g., commercial invoices, packing lists, certificates of origin) and who is responsible for preparing them.

- Customs Clearance: If shipping internationally, clarify who handles customs clearance and any associated fees.

- Freight Forwarding: Determine if the manufacturer offers freight forwarding services or if you need to arrange this independently.

- Tracking and Visibility: Inquire about shipment tracking capabilities and how you will be kept informed of the order’s progress.

- Insurance: Ask if the manufacturer offers shipping insurance or if you need to arrange your own coverage.

A reliable manufacturer will have established relationships with shipping carriers and freight forwarders, allowing them to negotiate favorable rates and ensure efficient transportation. Effective communication and collaboration between you and the manufacturer are essential for a smooth shipping process.

9. What is Your Environmental Commitment?

Nowadays, consumers are increasingly conscious of the environmental impact of their purchases. Partnering with a manufacturer committed to sustainability aligns your brand with ethical values and resonates with eco-conscious consumers.

Key areas to explore:

- Material Sourcing: Inquire about the manufacturer’s commitment to using sustainable materials, such as recycled stainless steel, bamboo, or ocean-bound plastics. Understanding their sourcing practices and certifications (e.g., FSC, RSPO) can provide valuable insights.

- Production Processes: Ask about the manufacturer’s energy efficiency initiatives, waste reduction efforts, and water conservation practices. Explore their use of renewable energy sources and their commitment to minimizing their carbon footprint.

- Packaging: Inquire about the type of packaging materials used and whether they are recyclable, biodegradable, or compostable. A focus on reducing packaging waste demonstrates environmental responsibility.

- Certifications: Look for certifications like ISO 14001 (Environmental Management System) or B Corp certification, which indicate a strong commitment to sustainability.

Conclusion

Selecting the right manufacturing partner for your custom drinkware project is an important decision that can significantly impact your brand’s success. By asking the right questions and conducting thorough research, you can identify a partner that aligns with your vision, delivers exceptional quality, and provides outstanding service.

From understanding a manufacturer’s expertise and product range to evaluating their quality control processes, lead times, and pricing structures, the information gathered through careful inquiry empowers you to make informed choices. Remember to consider factors such as customization options, design capabilities, logistics, and environmental commitment when assessing potential partners.

By investing time and effort in finding the ideal manufacturer, you can create drinkware that leaves a lasting impression on your customers and elevating your brand to new heights. Want to source personalized ones that are unique for you? At KingStar, we specialize in creating high-quality, custom-designed insulated flasks that exceeds expectations. Leave an online message or email sales@waterbottle.tech, and we will reply as soon as possible.