Contents

- 1. What are the popular printing techniques for cylindrical items like stainless steel tumblers/bottles?

- 2.What is the seamless printing on stainless steel tumblers/bottles?

- 3. What is the rotary printing on stainless steel tumblers/bottles?

- 4. How to achieve seamless design on water bottles by rotary printing?

- 5. Which is better: multi-pass printing, single-pass printing or helical printing?

- 6. What is Helix One Cylindrical Printer?

- 7. Helix Printer Helps Your Custom Printing Business Stand Out!

- 8. Conclusion

The Helix® ONE Benchtop Cylindrical Printer is a game-changing advancement in printing technology, specifically designed for stainless steel tumblers/bottles. This amazing machine excels at rotary printing, which allows for seamless designs to be printed all around the cylindrical surface. Seamless printing ensures that there are no visible breaks or interruptions in the design, resulting in a professional and polished finish. The Helix® printer takes full advantage of these techniques, giving all the all custom printing business owners the ability to create unique and personalized tumbler bottles that truly stand out from the competition. By harnessing the power of Helix®, custom printing businesses can elevate their offerings and differentiate themselves in the market by delivering visually appealing and highly personalized products. In the following sections, we will delve deeper into rotary and seamless printing on stainless steel tumblers, as well as explore the features and benefits of the must-have Helix® printer for any custom printing business.

1. What are the popular printing techniques for cylindrical items like stainless steel tumblers/bottles?

When it comes to printing cylindrical items such as stainless tumblers or bottles, sublimation and screen printing are two of the most widely used techniques. These methods offer distinct advantages but also have their respective limitations.

Sublimation is a printing technique that allows for full-color graphics to be transferred onto cylindrical objects through a heat-transfer process. It involves printing an image onto a special paper and then using heat to transfer the ink from the paper onto the surface of the cylinder. This method offers vibrant colors and excellent detail, making it suitable for photo-quality prints. However, achieving seamless artwork can be challenging with sublimation, as there may be inconsistencies where the artwork meets on the cylinder. Additionally, the process generates excess plastic waste, which is a concern in today’s environmentally conscious world.

On the flip side, screen printing is a more old-school technique where you use a stencil and ink to make a design on the cylinder’s surface. This method is often used for printing logos and simple graphics, allowing for 360-degree designs. While it can give decent results, it doesn’t quite match up to sublimation in terms of photo quality. Plus, there’s always a registration mark left behind on the final product, which might not be what you’re going for if you want a seamless look. On top of that, screen printing takes time as each color needs to dry before moving on to the next one.

The demand for seamless printing on custom-printed gift tumbler bottles is growing as more and more people want their designs to look flawless. This has led to the development of new printing techniques that can meet these requirements. Digital printing, also known as rotary printing, is becoming a popular solution for achieving seamless prints on cylindrical items like stainless tumblers and bottles. In the upcoming chapters, we will explore how these techniques are revolutionizing personalized drinkware.

2. What is the seamless printing on stainless steel tumblers/bottles?

Seamless printing on stainless steel tumblers or bottles refers to a printing technique that results in a smooth and continuous image or design on the surface of the stainless steel container, without any visible seams or borders. This type of printing is often achieved using advanced printing methods such as sublimation or rotary printing (also called digital printing), which allow for precise and detailed images to be transferred onto the metal surface.

Here we’d show you an example of seamless printing on stainless steel tumblers or bottles:

Imagine you want to customize a set of stainless steel tumblers for a special event or as a promotional gift. You want the stainless steel tumblers to feature a unique design that will stand out and leave a lasting impression.

To achieve this, you decide to opt for seamless printing. The first step involves selecting a high-resolution image or design that you want to print on the tumblers. This can be a logo, a pattern, or any other custom artwork that you deem suitable. Next, you send the design to a printing company that specializes in seamless printing on stainless steel. The printing company uses advanced printing equipment and techniques to transfer the design onto the surface of the tumblers. This process often involves the use of special inks and coatings that adhere to the metal surface, ensuring a long-lasting and durable print.

During the printing process, the image is printed onto the stainless steel in a way that eliminates any visible seams or borders. This means that the design flows smoothly and seamlessly across the surface of the tumbler, creating a visually appealing and professional-looking finish. Once the printing is complete, the stainless steel tumblers are ready for use. The seamless printing not only enhances the visual appeal of the tumblers but also adds a personal touch and makes them more memorable. Whether you’re using them for a corporate event, a wedding, or any other occasion, the seamless printing on stainless steel tumblers is sure to make a lasting impression.

3. What is the rotary printing on stainless steel tumblers/bottles?

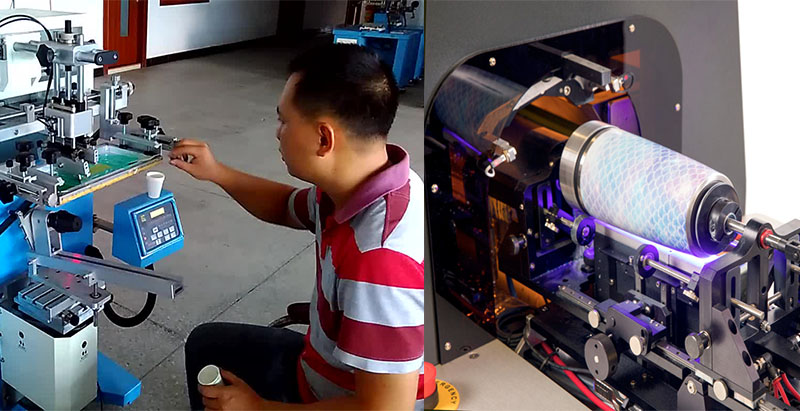

Rotary printing could be the best way to achieve a seamless print on your blank tumblers or bottles. When it comes to stainless steel tumblers or bottles, rotary printing is the go-to method for printing on cylindrical surfaces. This technique involves using a rotary printer that spins the tumbler or bottle while applying ink or other materials, resulting in a smooth and consistent design. The process starts with preparing the stainless steel tumblers or bottles by cleaning and treating their surfaces to ensure proper ink adhesion. Then, a stainless steel tumbler is placed securely onto the printer’s rotating fixture during printing.

Next, the printer’s inkjet heads or printing plates move along the length of the tumbler, applying ink to the surface as it rotates. The ink is precisely applied to create the desired design, which can include logos, graphics, text, or any other customized element. The printer’s advanced controls ensure that the ink is evenly and smoothly applied without any breaks or imperfections. The rotary printing process offers several advantages for stainless steel tumblers and bottles. Firstly, it allows for vibrant and detailed full-color prints. The ink adheres well to the stainless steel surface, resulting in long-lasting and durable designs. Secondly, seamless application of ink gives a professional and polished appearance that is hard to achieve with other printing methods.

Moreover, rotary printing is super flexible and can handle a wide range of tumbler sizes and shapes. This makes it perfect for both small-scale and large-scale production runs. Plus, the printing process can be automated, making it even more efficient and reducing production time.

4. How to achieve seamless design on water bottles by rotary printing?

Actually, we need a professional rotary printing machine to fully design custom tumblers or bottles. But first, let’s talk about the common ways to do rotary printing. Rotary printing is a technique that uses a rotating press and it’s an efficient and effective way to achieve seamless designs on water bottles. This method involves using a cylindrical surface that rotates while applying ink to the bottle, resulting in a smooth and continuous print. When it comes to rotary printing for water bottles, there are three main methods: multi-pass printing, single-pass printing, and helical printing. Each method has its own advantages and considerations for achieving seamless designs.

- Multi-pass printing: In multi-pass printing, the print head moves back and forth across the tumbler’s surface several times to complete the design. This method works well for intricate designs or when you need a lot of detail. However, it can be slower because it requires multiple passes. Also, for larger designs, there might be visible lines where the different sections are stitched together, which can interrupt the seamless look.

- Single-pass printing: The single-pass printing method is super fast and efficient because the print head only needs to go across the bottle once. It’s perfect for simple designs or when speed is a top priority. However, it might not work as well for wider designs since the print head’s width could be a limitation. In that case, you may need multiple print heads or stitching to achieve the seamless effect.

- Helical Printing: The helical printing technique, also known as spiral printing, is a cool way to create awesome designs on water bottles. Instead of just moving in a straight line, the print head moves in a spiral pattern around the bottle, slightly overlapping each pass to make sure the design seamlessly flows together. This means you get smooth and even ink coverage without any visible lines or stitching marks. Helical printing works especially well for round or cylindrical shapes like water bottles because it can perfectly follow the curves of the surface.

5. Which is better: multi-pass printing, single-pass printing or helical printing?

Among the three methods mentioned, helical printing is the best rotary printing technique for creating full designs on your stainless steel tumblers. This advanced printing method has many advantages that make it the top choice for achieving visually appealing and functional tumblers. As I mentioned earlier, helical printing involves the print head moving in a continuous spiral pattern around the tumbler’s surface. This ensures a smooth flow of ink, resulting in a design without any visible lines or stitching marks. The overlapping of each pass guarantees even ink coverage, creating a seamless and consistent design that wraps around the entire tumbler. Additionally, helical printing offers high precision and accuracy. The printer can be calibrated to align perfectly with the tumbler’s surface, resulting in clear and crisp designs. This level of precision is essential for achieving flawless designs that are both visually pleasing and functional.

In addition to looking seamless, helical printing also offers a wide range of design options. You can create anything from simple patterns to intricate illustrations using this technique, making your tumbler designs unique and eye-catching. The best part is that you can customize the designs according to your customers’ specific needs and preferences, which makes helical printing perfect for personalized tumblers. And let’s not forget that it’s highly efficient and cost-effective too! With fast and continuous printing, it reduces production time and costs, making it a great choice for businesses that need to produce large quantities of tumblers with seamless designs. Click and read more: Laser Engraving Business Owner’s Bulk Water Bottles Tumblers Buying Guide

6. What is Helix One Cylindrical Printer?

The Helix One Cylindrical Printer is a professional cylindrical printer for your desk that uses helical printing technology to create vibrant, full-color graphics on a wide range of cylindrical objects. This printer is designed to give you seamless and high-quality prints, turning plain stainless steel tumblers or bottles into eye-catching and valuable pieces.

One of the cool things about the Helix One is that it can print seamlessly on curved surfaces. The helical printing technology lets the printer make a continuous design that wraps around objects like tumblers, giving them a smooth and attractive look. This not only makes the product look better but also adds more value to it. Another great thing about this printer is its versatility. It works with LV series UV ink and can decorate all sorts of materials, including plastic, acrylic, stainless steel, and powder-coated surfaces. This means you can use it for lots of different things, from personalized drinkware and gifts to industrial parts and labels.

In terms of performance, the Helix One Cylindrical Printer is awesome with a maximum resolution of 600 x 1200 dpi, guaranteeing super clear and detailed prints. It can handle cylindrical objects with diameters ranging from 1.77 inches to 4.7 inches and lengths from 2 inches to 13 inches, so it’s perfect for all different sizes. The Helix One’s desktop design also adds to its convenience and ease of use. It doesn’t take up much space at all, so you can use it at home or in the office without any problems. The user-friendly interface and stable performance make printing a breeze, allowing you to finish your tasks quickly and efficiently.

7. Helix Printer Helps Your Custom Printing Business Stand Out!

In the world of custom printing, it’s crucial to stand out from the competition and offer unique, personalized products in order to succeed. The Helix Printer specializes in cylindrical printing and provides an innovative solution that can take your custom printing business to the next level, especially when it comes to creating breathtaking designs on stainless steel tumblers or bottles.

We all know that reusable water bottles like stainless tumblers represent the new trend of lifestyles. Stainless steel tumblers are incredibly popular items, often used as promotional giveaways, corporate gifts, or simply as personalized drinkware. However, most printing services are limited to flat surfaces, making it difficult to create truly unique designs on cylindrical objects like tumblers. This is where the Helix Printer shines. Its ability to print directly onto the curved surface of the tumbler allows for seamless, high-resolution graphics that wrap around the entire circumference. This not only creates a visually stunning product but also ensures that the design is fully integrated into the shape of the tumbler, enhancing its overall appeal.

Moreover, the Helix Printer’s precision and color accuracy ensure that the prints are vibrant and long-lasting. This is particularly important for stainless tumblers, which are often used in high-traffic areas like cafes or offices. The durability of the prints ensures that your customers can enjoy their personalized tumblers for a long time without worrying about fading or peeling.

Similarly, for stainless bottles, the Helix Printer offers the same advantages. Whether it’s a water bottle, a sports drink container, or a promotional flask, the printer can transform these ordinary items into eye-catching, personalized products. The ability to print directly onto the cylindrical surface means that even complex designs or logos can be reproduced with ease, making each bottle truly unique.

By offering custom stainless tumblers or bottles printed with the Helix Printer, your custom printing business can set itself apart from the competition. Not only will you be able to attract new customers with your unique products, but you’ll also be able to build stronger relationships with your existing customers by offering them personalized gifts that they’ll cherish.

8. Conclusion

The Helix Printer is a game-changer for your custom printing business. With its unique cylindrical printing capabilities, it allows you to create personalized stainless tumblers or bottles that will make your products really stand out from the competition. KingStar, a leading wholesale manufacturer of stainless steel drinkware, has an impressive production line that not only produces various types of high-quality water bottles and tumblers but also offers customized services. Using advanced technologies, we are proud to introduce the HELIX® ONE BENCHTOP CYLINDRICAL PRINTER, which is a perfect example of our commitment to innovating custom drinkware. Our customers absolutely love how this printer can effortlessly create seamless rotary designs on stainless steel tumblers or bottles, making it an invaluable addition to our range of personalized tumblers or bottles.

If you want more information about purchase full printing or purchasing wholesale blank metal water bottles / vacuum flasks / bulk insulated tumblers / plain thermos coffee cups, , please feel free to leave online message or send email to sales@waterbottle.tech!