When it comes to choosing stainless steel for manufacturing products like water bottles, two types often come up in the discussion: Type 304 and Type 201. While both are popular in various industries, particularly in the production of water bottles and other drinkware, they have distinct characteristics that can influence your purchasing decisions.

As the leading expert in manufacturing custom stainless steel water bottles, we understand how crucial it is for suppliers and wholesalers to make informed decisions about the materials they choose for their products. In this guide, we’ll break down the key differences between 304 and 201 stainless steel, their pros and cons, and how to decide which one suits your market.

What Is Stainless Steel Type 304?

Type 304 stainless steel, also known as “18/8 stainless steel,” is one of the most commonly used and versatile grades of stainless steel. It contains a mixture of iron, chromium (18%), and nickel (8%), which makes it highly resistant to rust and corrosion. Type 304 is often referred to as “food-grade” stainless steel due to its use in a wide range of applications, including kitchen equipment, water bottles, medical devices, and food processing equipment.

Some of the key characteristics of Type 304 include:

- Corrosion Resistance: Offers excellent resistance to corrosion and rust, especially when exposed to water, air, and a wide range of environmental conditions.

- Durability: Thanks to its nickel content, Type 304 stainless steel is more resistant to oxidation and maintains its strength over time, even in harsh conditions.

- Non-reactivity: Type 304 is non-reactive, meaning it won’t interact with acidic or alkaline substances, making it perfect for items like water bottles that come in contact with liquids over time.

- Easy to Clean: This material is very easy to clean, which is important for products like water bottles where hygiene is a key concern. Its smooth surface prevents the buildup of grime and bacteria.

What Is Stainless Steel Type 201?

Type 201 stainless steel is a lower-cost alternative to Type 304, often referred to as “budget stainless steel.” It contains a similar amount of chromium (about 16%) but has a lower nickel content (around 3-5%) and includes manganese as a replacement for some of the nickel. This gives Type 201 a different set of properties and makes it less expensive than Type 304.

Some characteristics of Type 201 include:

- Corrosion Resistance: While Type 201 has good resistance to corrosion, it’s not as effective as Type 304. It’s more susceptible to rust in certain environments, especially if exposed to salty or acidic substances for long periods.

- Strength: Type 201 is generally stronger than Type 304, but its resistance to oxidation and corrosion is not as robust, making it more suitable for indoor or less aggressive environments.

- Magnetic Properties: Unlike Type 304, Type 201 is magnetic, which could be a consideration for certain manufacturing processes or designs.

- Cost-Effective: One of the biggest advantages of Type 201 is its affordability.

- Slightly Less Durability: While Type 201 stainless steel has good durability, it’s not as long-lasting as Type 304, especially in high-moisture or high-temperature environments.

SS304 vs. SS201: Side-by-Side Comparison

Let’s break down their differences in a supplier-friendly format:

| Feature | SS201 | SS304 |

|---|---|---|

| Composition | Contains lower nickel content (about 3-5%) and higher manganese (about 7-10%) | Contains about 8% nickel and 18% chromium |

| Corrosion Resistance | Lower corrosion resistance. Prone to pitting or discoloration in humid or salty environments. | High corrosion resistance, ideal for exposure to water and food-grade applications |

| Cost | More affordable due to lower nickel content | More expensive due to higher nickel content |

| Durability | Less durable, can show signs of wear faster in extreme conditions | Highly durable and resistant to wear and tear, maintains integrity over time |

| Heat Resistance | Less heat-tolerant. Prolonged high heat can weaken its structure. | Handles extreme temperatures (up to 1600°F/870°C) without warping. Perfect for sterilizing bottles or handling hot beverages. |

| Food-Grade | Not considered food-grade due to lower corrosion resistance | Considered food-grade, ideal for kitchen and beverage containers |

| Aesthetic Quality | May become cloudy or scratched over time | Maintains a shiny, glass-like finish that doesn’t discolor easily |

| Common Applications | Used for outer walls of containers, low-cost applications | Used for both inner and outer walls of high-end containers, kitchenware, food-grade products |

| Impact Strength | Good, but less resilient than SS304 | Excellent impact strength, won’t crack or shatter easily |

| Magnetism | Slightly magnetic due to higher manganese content | Non-magnetic or weakly magnetic, depending on processing |

Summary:

- SS201 is a more cost-effective option with lower corrosion resistance and durability, typically used for the outer layer of products where corrosion is not a critical concern.

- SS304 is ideal for high-end, food-grade products due to its superior corrosion resistance, durability, and aesthetic appeal, making it the better choice for high-performance drinkware and kitchen containers.

Choosing between SS210 and SS304 depends on your product’s needs, including performance, budget, and the required level of corrosion resistance.

SS304 vs SS201 in Water Bottles: Which One Is Better?

When it comes to manufacturing water bottles and drinkware, the choice between SS304 and SS201 depends on the intended use and specific requirements. Both materials have their merits, but they differ in certain critical ways. Let’s break down where each type of stainless steel excels and where it falls short.

SS304 Stainless Steel: Ideal for High-Quality Drinkware

Usage in Water Bottles: SS304 is commonly used for both the inner and outer walls of double-walled water bottles. Its high corrosion resistance ensures that the bottle remains hygienic and safe for long-term use, even when exposed to water, drinks, and other liquids. It’s also highly resistant to staining, ensuring that the bottle maintains a clean, aesthetically pleasing appearance.

Advantages:

- Food Safety: SS304 is widely recognized as food-grade stainless steel, making it an ideal choice for water bottles that come into direct contact with liquids.

- Long-Term Durability: SS304 bottles are built to last. They are resistant to rust, corrosion, and staining, ensuring that the bottles can withstand years of use without deteriorating in quality.

- Heat Resistance: SS304’s ability to withstand high temperatures makes it perfect for bottles that need to handle both hot and cold beverages, as it maintains structural integrity without degrading.

Disadvantages:

- Cost: SS304 is generally more expensive than SS201 due to its higher nickel content and enhanced properties, which may increase the production cost of water bottles.

SS201 Stainless Steel: A Budget-Friendly Option for Drinkware

Usage in Water Bottles: SS201 is often used for the outer wall of double-walled bottles, especially in products where cost savings are a priority. Since it has lower corrosion resistance compared to SS304, it is not typically used for the inner lining of bottles where hygiene and direct contact with liquids are critical. Remark: KingStar never use SS201 to build inner wall of any drinkware.

Advantages:

- Cost-Effective: SS201 offers a more affordable alternative to SS304, making it a good choice for budget-conscious manufacturers or suppliers looking to offer more affordable products.

- Good for Outer Walls: While SS201 is not ideal for the inner part of the bottle, it can work well for the outer wall of the bottle, especially for products where aesthetics are important but the need for food-grade safety is not as critical.

Disadvantages:

- Lower Corrosion Resistance: SS201’s lower corrosion resistance makes it less suitable for long-term exposure to liquids, especially in humid or high-moisture environments. This makes it less ideal for use in the inner lining of bottles.

- Not Food-Grade: SS201 is generally not considered food-grade, meaning it may not meet the required safety standards for direct contact with consumables.

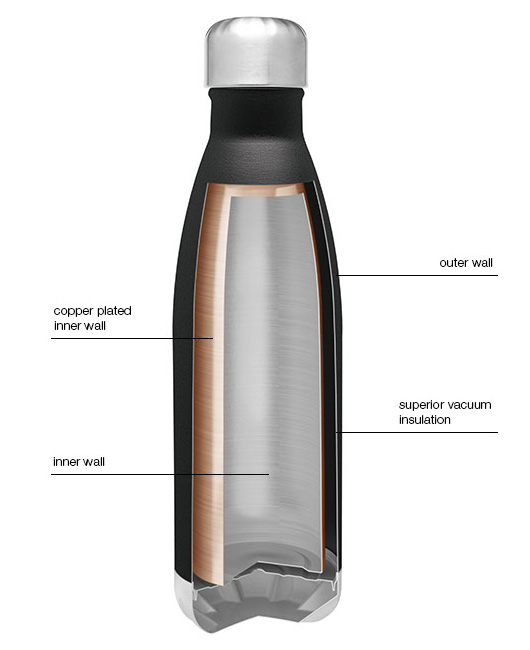

SS304 vs SS201 in Double-Walled Containers

Double-walled containers, including thermos bottles and vacuum flasks, are designed to maintain the temperature of their contents for extended periods of time. Both SS304 and SS201 are used in these containers, but they serve different purposes.

- SS304: It is commonly used for both the inner and outer walls of double-walled containers in high-end products. Also, it’s typically used for bottle caps, handles, and trim. Its superior corrosion resistance and ability to withstand high temperatures make it perfect for keeping liquids hot or cold without compromising the integrity of the container.

- SS201: This is typically used for the outer wall of double-walled containers, where its lower cost is a key consideration. While it still provides adequate protection, it doesn’t offer the same level of durability and corrosion resistance as SS304.

Common Myths Debunked

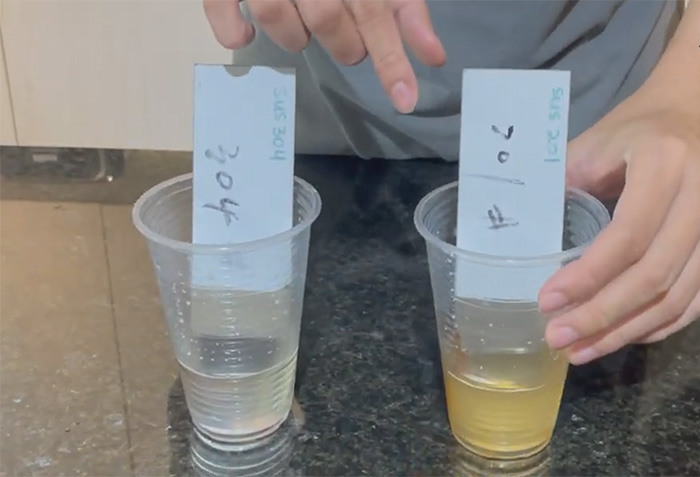

Myth 1: “All stainless steel is rust-proof.”

- False: Only high-grade steels like 304 resist rust long-term. 201 may corrode if scratched or exposed to saltwater.

Myth 2: “Nickel in 304 is unsafe.”

- False: The nickel in 304 is bound tightly; it won’t leach into drinks under normal use. (It’s FDA-approved for food contact.)

Myth 3: “201 steel bottles are just as good.”

- Depends: For temporary use, yes. For daily hydration, 304 is far more reliable.

Conclusion

Choosing between 304 and 201 stainless steel isn’t about “better” or “worse”—it’s about matching the material to the job. Use 201 for cost-sensitive, non-critical parts, and rely on 304 for safety and durability where it counts.

At KingStar, we specialize in high-quality, custom stainless steel water bottles, and empower suppliers with customizable options for both grades, ensuring you meet diverse market demands without compromising on safety or satisfaction. Whether you’re looking for premium SS304 or cost-effective SS201 options, we can help you for your business.

Reach out to us today to request free material samples or discuss bulk pricing for your next order. Let’s build drinkware that keeps your customers hydrated—and your business thriving.