As a part of the stainless steel water bottle reliability test, the fatigue test of the lid aims to obtain the fatigue performance of the lid that withstands alternating loads under various conditions, and study the fracture process of the lid. The Quality Department in KingStar is responsible for the implementation of both fatigue tests and aging tests of varied products based on standards including ISO, ASTM, DIN, GB and HB, and evaluate the feasibility of design as well as the product reliability during the development of new products.

The fatigue test of the lid is always ignored by many water bottle manufacturers, and even some experienced buyers are unaware of the procedure, principle and importance of it. As a result, quality issues occur on some products picked up by them after a certain time of use. These quality problems include deformed and slipping screw threads of the lid, leakage and breakage of the lid.

As a leading water bottle manufacturer, KingStar will share the detailed steps and methods of the water bottle fatigue test with wholesalers and vacuum flask manufacturers in the article for your reference & discussion.

-

Testing Object

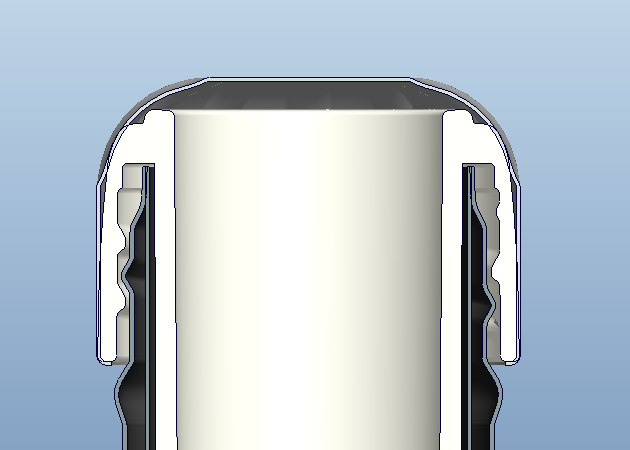

Stainless Steel Water Bottle Lid

Stainless Steel Water Bottle Thread

Hydro Vacuum Flask Thermos Drink Bottles

-

Testing Range

- The stress (strain) and life (cycles) of the tested bottle lid: high cycle fatigue, low cycle fatigue, room temperature fatigue, low temperature fatigue, high temperature fatigue, thermal fatigue, test environment, corrosion fatigue, contact fatigue, fretting fatigue, etc.

- Loading method: tension and compression fatigue, bending fatigue (rotating bending fatigue, three-point bending fatigue, four-point bending fatigue, cantilever bending fatigue), twisting fatigue, compound stress fatigue, etc.

-

Testing Method

- Take the stainless steel water bottle lid required for the test, and measure its original size with a vernier caliper. Lids with processing defects on its surface shall not be used.

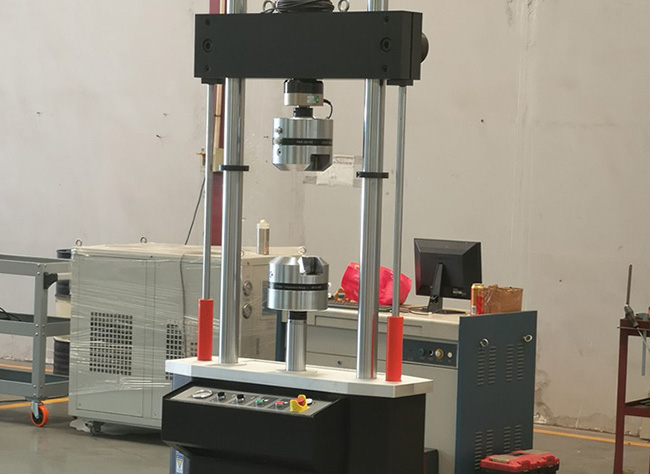

- Before using the fatigue testing machine, please keep the equipment checked and read the manual.

- Turn on the machine and set various testing parameters.

- Determine the height of the bottle and the screw before installing the bottle.

- Install the lid. Maintain good coaxiality between the sample and the main shaft of the testing machine.

- Check if the cam is at the front or the end.

- Tighten the lid of the bottle, and the cam should be on the back, otherwise the lid is in the loose position.

- Perform static test. Take one of the qualified samples, and test its σb by tensile test first. The purpose of the static test is to check whether the strength of the material meets the heat treatment requirements, and determine the stress levels at all levels based on it.

- The required rotation of 360 degrees is 14 teeth, and 1.552 times the length from the center of the cam to the center of the reducer is the actual stroke. Make sure that the torque force has a certain pre-pressure because the torque force continues to decrease (the maximum torque is 29.5KG) as the number of exercises increases if there is no pre-pressure, and the over-range is invalid, which can be determined according to the needs.

- The fatigue degree of the bottle thread can be determined by the 3 inspection methods below:

I. Torque change degree (when the pre-pressure is low)

II. Length inspection (when the pre-pressure is high)

III. Tighten the bottle and the lid with a mark to see the change.

Results of the above three methods need to be recorded according to the test times. For example, record the changes when the movement is repeated 5 thousand times and 10 thousand time respectively to meet product design need.

- Observe and record. The test shall be performed from high stress to low stress level. Record the cycles number of each sample’s fracture, and observe the location and characteristics of the fracture simultaneously.

- When the test is finished, remove the lid of the bottle, clean up the testing site and put testing machines in place.

Note: Clear the counter before starting automatic counting to ensure the accuracy of counting.

-

Methods to Improve the Results of Fatigue Testing

- Optimize the design mechanism of the lid

- Optimize thread parameters

- Choose appropriate materials according to the material of the bottle, the inner & outer layer of the lid, etc.

If you have any questions related to the reliability test of stainless steel water bottle lid, to the manufacturing of insulated bottles, or to custom water bottle & tumblers & cups in bulk, please contact us.