Engraving on stainless steel water cups has become a popular way to add personalization and artistic appeal to insulated stainless steel bottles. Whether you want to engrave a custom design, logo, or text onto your cup, there are several methods available to achieve this, including machine laser engraving, etching engraving, and metal penetration engraving. Among these options, laser engraving stands out as a highly precise and durable method, offering a wide range of advantages. In this guide, we will explore the various techniques for engraving on stainless steel cups and delve into the best way to laser engrave insulated stainless steel cups. Additionally, we’ll address common concerns about the longevity of engraved markings on stainless steel and provide practical tips to ensure successful laser engraving projects.

1. How to engrave on a stainless steel water cup?

Engraving on stainless steel water bottles / tumblers / coffee cups / metal dog bowls / food containers / lunch boxes / insulated vessels etc can be done using the following three methods.

Machine laser engraving

- Place the stainless steel water bottle on the engraving surface of a laser engraving machine.

- Use the laser engraving machine to automatically engrave the design or text onto the stainless steel surface.

Etching engraving

- Print the desired design onto the surface of the stainless steel water cup using a screen printing technique and protect the areas that do not need to be etched.

- Place the printed cup into an acidic etching tank.

- By agitating the etching tank, the acidic liquid will corrode the unprotected stainless steel surface, creating the engraved effect.

Metal penetration engraving

- This method requires the use of a cutting machine.

- Import the desired design into the cutting machine and perform automatic cutting using a computer.

- The cutting machine will cut out the pattern and text on the stainless steel surface, creating a perforated effect.

- This method allows for highly precise engraving effects and is particularly suitable for intricate patterns and text.

2. What is the best way for laser engraving insulated stainless steel cups?

Among these engraving methods, laser engraving insulated stainless steel jugs / wholesale blank vacuum flasks is a popular and effective method for adding personalized designs, logos, or text to such insulated stainless steel water bottles. The process involves using a high-powered laser beam to remove the surface material of the cup, creating a permanent, precise, and detailed mark. Its advantages can be listed as follows:

- High precision: Laser engraving allows for extremely fine detailing, enabling complex patterns, intricate text, or personalized logos to be engraved on the surface of the stainless-steel cup.

- Durability: Laser engraving permanently fuses the design or text into the stainless-steel surface, preventing easy wear or fading, unlike printing or stickers.

- Aesthetics: Laser engraving produces a visually appealing effect with a unique texture, adding value and artistic appeal to the cup.

- Safety: Laser engraving is a non-contact processing method, ensuring no physical damage or deformation to the cup.

- Material versatility: Laser engraving can be applied to various materials, including wood, glass, leather, plastic, not limited to stainless steel. It can be used for engraving other items such as nameplates, gifts, and decorations.

- Mass production: Laser engraving technology can be combined with computer control systems to achieve automated production and large-scale processing, making it suitable for mass-producing cups or other engraved products.

- Environmentally friendly and energy efficient: Compared to traditional engraving processes, laser engraving does not require ink, chemicals, or solvents, reducing environmental pollution. Additionally, laser devices have relatively low energy consumption, promoting energy conservation and emission reduction.

- Efficiency: Laser engraving has high working efficiency, allowing for quick completion of complex engraving tasks, making it widely used in commercial customization and personalized gift manufacturing.

- Artistic expression: Laser engraving technology can adjust laser power, frequency, and scanning paths to achieve varying depths and colors, thereby enhancing artistic expression.

- Anti-counterfeiting and identification: Laser engraving can create unique marks or serial numbers on products, serving purposes such as anti-counterfeiting and identification, especially for premium cups, luxury goods, and identity documents.

3. Will the words or patterns engraved on the stainless steel water cups fade?

Generally, the words engraved on a blank stainless steel water bottles are quite durable and won’t easily come off or fade. Stainless steel is a robust material, and its characteristics make the engraved text resistant to wear and peeling. Here are some reasons:

- Stainless steel’s corrosion resistance: Stainless steel is composed of iron, chromium, and other alloy elements, with at least 10.5% chromium content. This gives stainless steel excellent corrosion resistance, protecting it from oxidation and corrosion.

- Laser engraving: Typically, engraving on a stainless steel water cup is done using laser technology. Laser engraving creates deep grooves that firmly bond with the surface, making it difficult to wear off or come off easily.

- Surface treatment of stainless steel: Stainless steel water cups will undergo surface treatments such as polishing or sandblasting to increase surface smoothness and durability. These treatments help protect the engraved text from everyday usage.

While the words engraved on a stainless steel water cup are unlikely to come off, it’s essential to note that using sharp or hard metal objects to scratch the cup’s surface could still cause damage to the engraved text or the surface. Treating the cup with care will ensure that the engraved text remains long-lasting.

4. What are the tips for laser engrave insulated stainless steel cups?

Tip 1 – Prepare artwork and materials

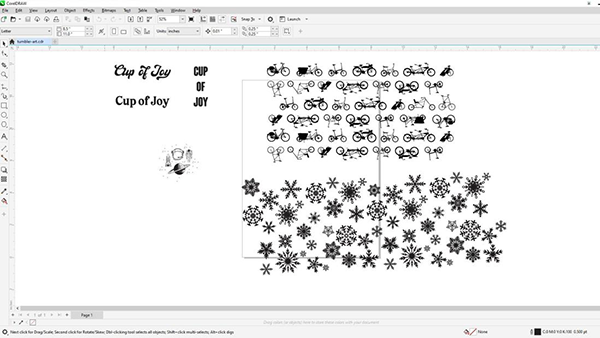

Download the graphics above or import your own drawings, text, photos, or graphics. Modify as needed.

Tip 2 – Setup

- Spray the stainless steel cup: Spray a layer of even metal marking compound on the area of the cup where engraving is required. If you have a fiber laser machine, you can skip the pre-processing step as these systems are designed for direct marking on metal. Be sure to check your user manual for recommended settings specific to the metal you’re working with.

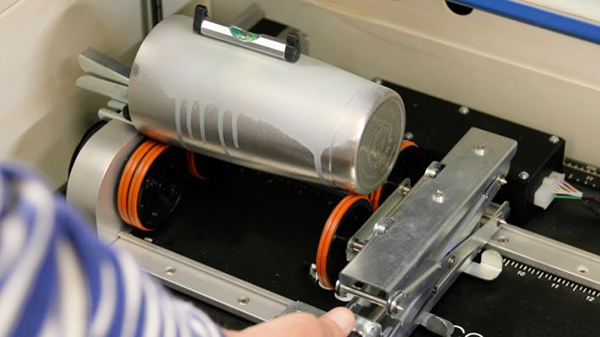

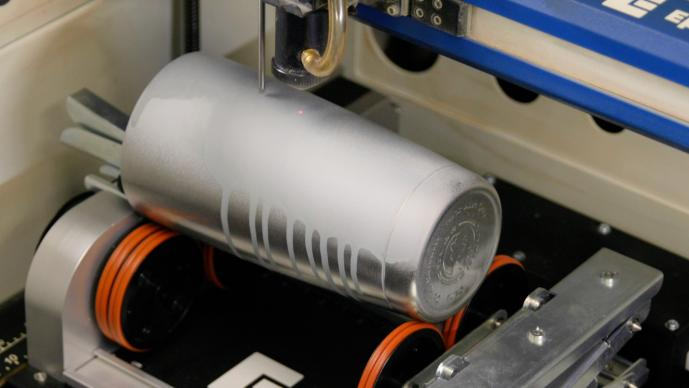

- Install the rotary accessory: Lower the engraving table to make space for the rotary accessory in the machine. Turn off the machine power and then insert the rotary accessory before restarting the laser machine. The laser head will now be positioned at the new starting point of the rotary accessory.

- Insert the cup: Place the stainless steel cup on the rotary accessory. Use shims to ensure the piece remains level throughout, and then manually focus the machine. If you’re using the center engraving feature, set a new starting position at the center of the workpiece and use the red dot pointer as a guide.

Tip 3 – Determine parameters

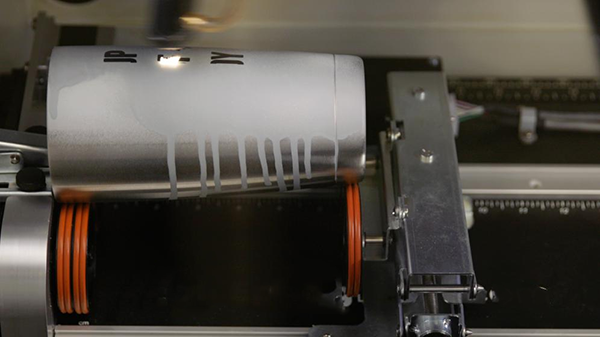

Select the recommended settings for engraving stainless steel on the laser engraving machine panel. Alternatively, you can refer to the user manual for engraving/cutting settings recommended for your laser machine and wattage. Input your settings in the panel and then send the job to the laser machine.

Tip 4 – Send your job to the laser machine

Use the correct parameters corresponding to the wattage of your machine to send the job to the laser.

Tip 5 – Rinse the cup

After the graphic engraving is completed, rinse off the marking compound with water, and your brand-new custom stainless steel cup is ready to use or gift!

If you want more information, please contact us!

Try to source a reliable wholesale blank water bottle tumbler supplier for your laser engraving business? KingStar is your best choice. KingStar is the leading wholesale stainless steel drinkware manufacturer factory in China with best price and quality. Send an email to sales@waterbottle.tech to get a free quote and samples!