The SPI (Society of Plastics Industry) and the GPI (Glass Packaging Institute) have developed a standardized set of guidelines to ensure consistency in the threading of containers. These standards provide specifications for several key aspects of container threads, including the number of thread turns, the spacing between threads, thread height, top beads, and whether the threads are continuous or non-continuous.

A clear understanding of bottle neck and cap finishes, thread sizes, and dimensions is crucial when designing custom drinkware, such as water bottles, vacuum flasks, insulated cups, stainless steel tumblers, pints, vessels, and food containers. Proper measurements are necessary to ensure a secure, sealed fit. As a leading custom water bottle manufacturer, we compile this guide which covers the key aspects about water bottle neck finishes.

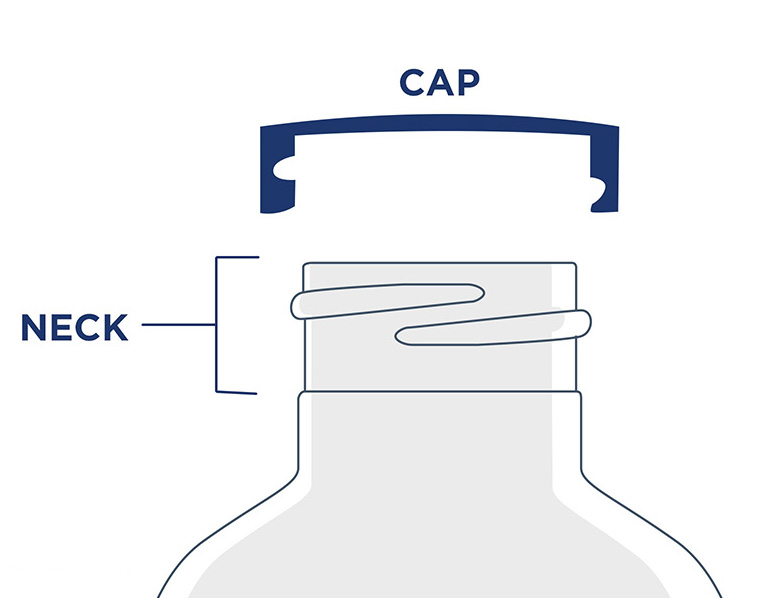

What is a Water Bottle Neck?

The neck of a water bottle refers to its narrowest part, where the opening is smaller than the diameter of the bottle’s body. Bottle designs naturally taper to form this neck, which accommodates the smaller mouth. This narrowing provides better control when handling the bottle and allows for compatibility with various lids / caps.

What is a Bottle Neck Finish? What does 60/400 Mean?

The neck finish of a bottle refers to the area where the outer threads on the neck connect with the cap or closure, securing the lid in place. The term “neck finish” is commonly used with bottles, as it describes the narrow section leading to the smaller opening. For wider-mouth containers or jars, the term “thread finish” is more frequently used. Despite the different terms, both refer to the same part of the container where the closure meets and seals the opening.

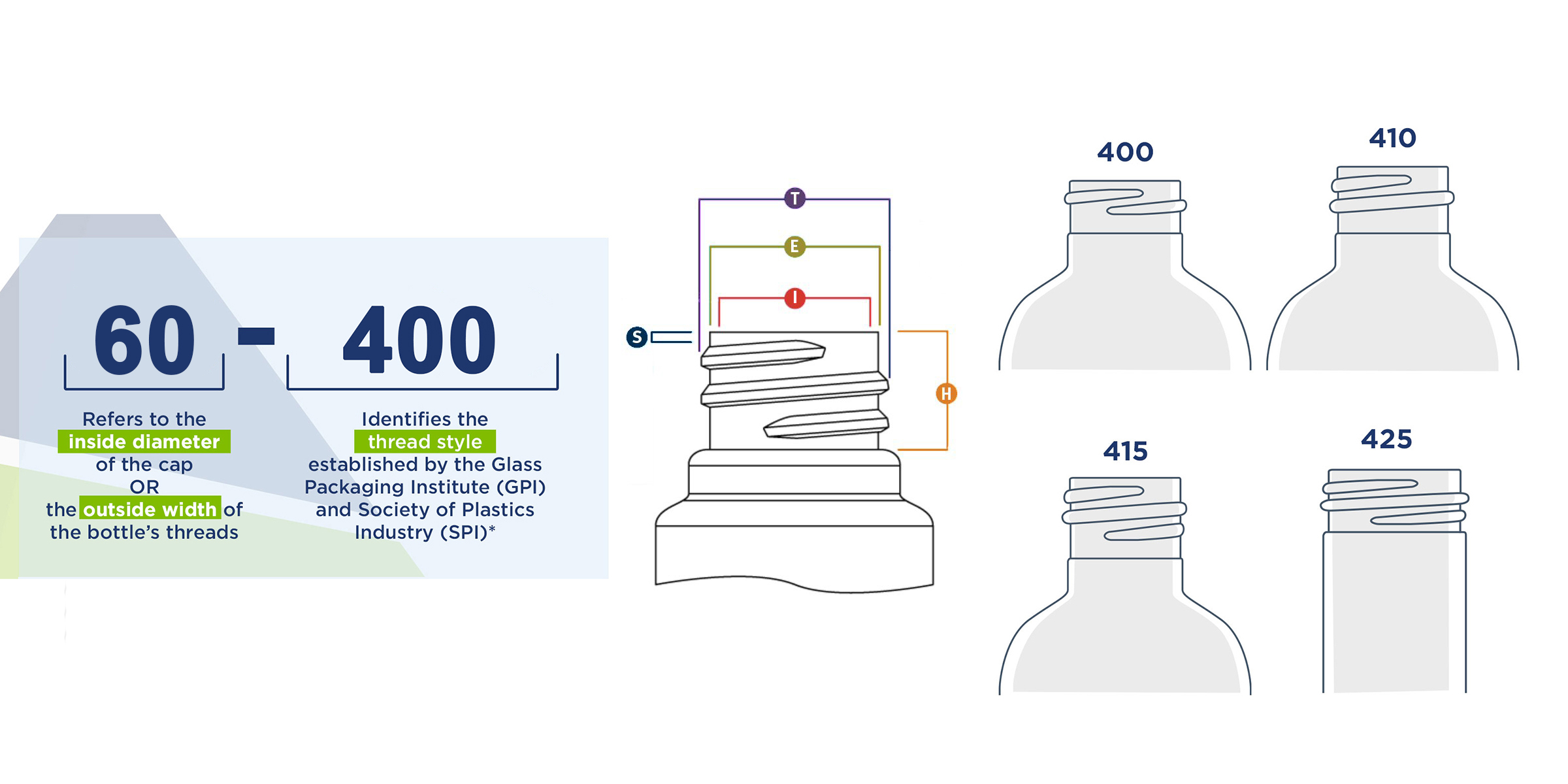

Water bottle manufacturers specify neck width and thread style in their product descriptions. These neck finishes are typically represented by:

– A two-digit number (neck width)

– A three-digit number (thread finish)

These numbers are shown as 60-400 or 60/400 or a single number like 60mm.

For example, in a 60-400 neck finish:

– “60” represents the “T” dimension, or the neck width, which measures the diameter across the neck opening, including the threading, in millimeters.

– “400” refers to a single thread turn around the container’s neck, indicating the thread finish.

Water Neck Measurement

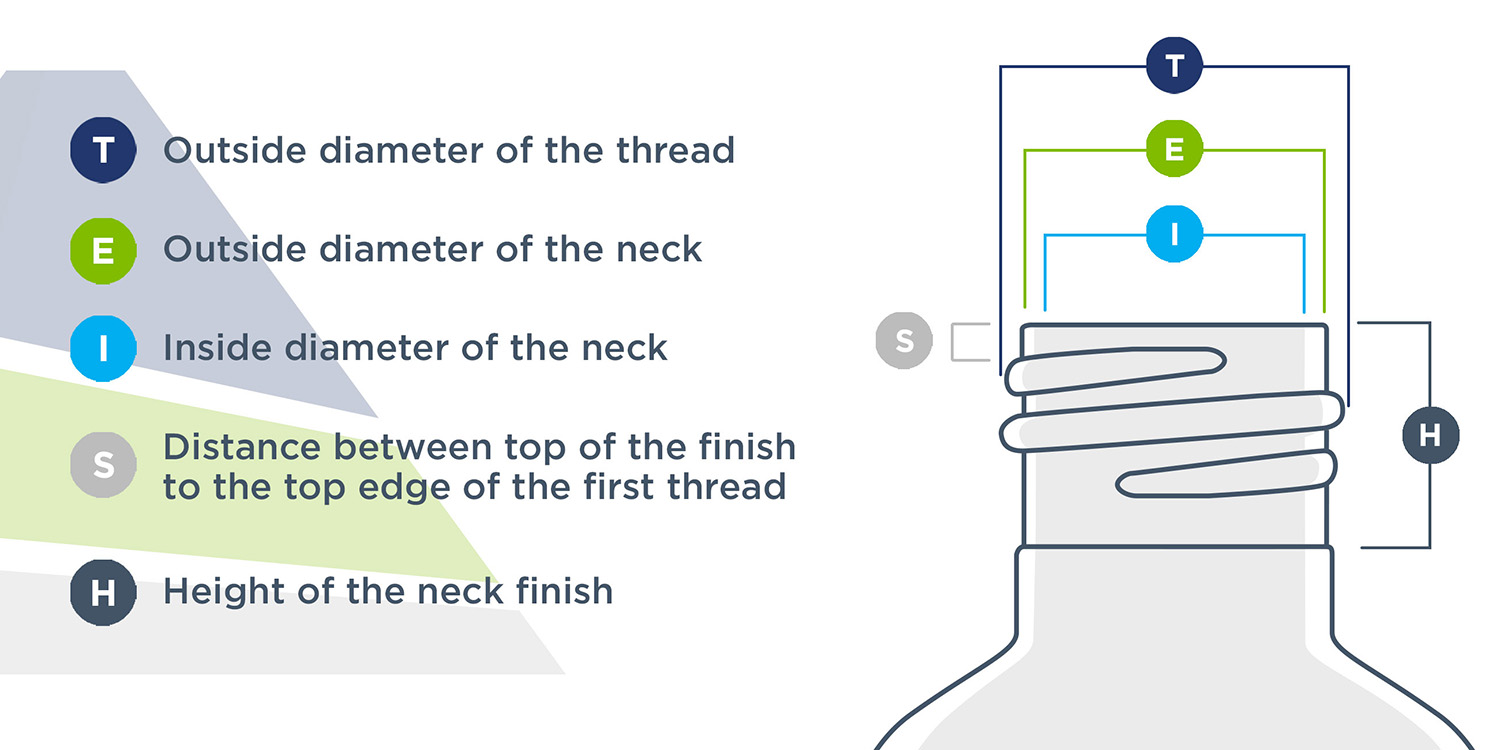

**”T” Dimension**

The “T” dimension refers to the measurement of the outer diameter of the thread on the bottle neck. This measurement is crucial for determining the appropriate closure that will fit the bottle.

**”E” Dimension**

The “E” dimension measures the outer diameter of the bottle neck itself. The depth of the thread is calculated by taking the difference between the “E” and “T” dimensions, divided by two.

**”I” Dimension**

The “I” dimension is the inner diameter of the bottle neck. This specification is essential to ensure there is enough clearance for filling tubes. A precise “I” dimension is also necessary for linerless closures with plug or land seals, as well as dispensing plugs and fitments, to achieve a proper fit.

**”S” Dimension**

The “S” dimension measures the distance from the top of the neck finish to the top edge of the first thread. This measurement is key in determining how the cap aligns with the bottle and how much thread engagement occurs between the bottle and the cap.

**”H” Dimension**

The “H” dimension represents the height of the neck finish. It is measured from the top of the neck down to where the “T” dimension (the outer diameter of the thread) intersects with the shoulder of the bottle.

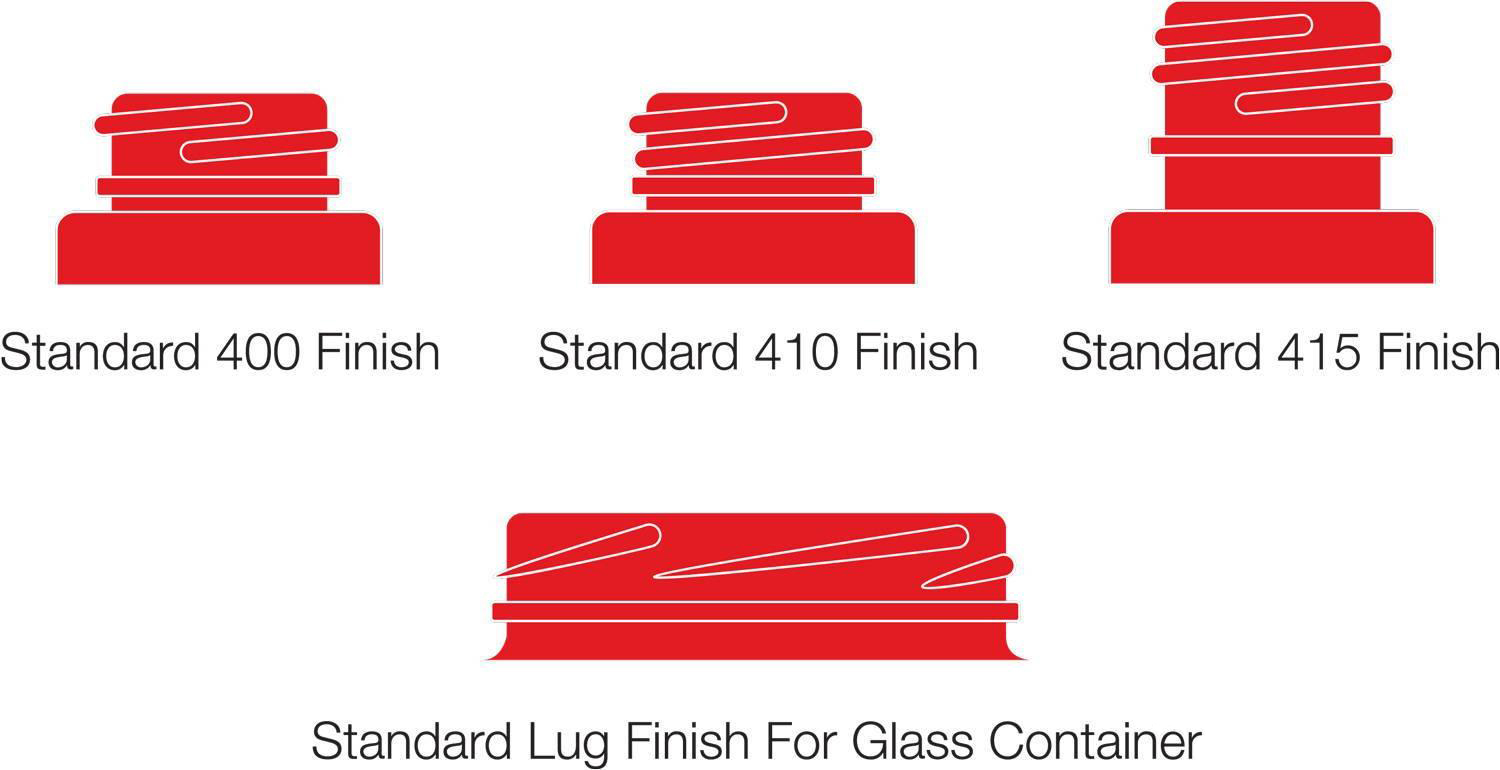

Continuous Thread Finishes

A continuous thread (CT) finish is one of the most common closure systems found on glass, metal, and plastic containers. This type of thread is characterized by a continuous, unbroken spiral wrapping around the neck of the container. The smooth, uninterrupted thread design allows for easy screwing and unscrewing of the cap, providing a reliable, secure closure for a wide range of products. Continuous thread finishes are widely used.

Here’s a breakdown of various continuous thread neck finishes:

**400 Neck Finish**

A 400 neck finish indicates one complete thread turn around the neck of the container. This is the most basic form of continuous threading and is commonly used for standard-sized bottles.

**410 Neck Finish**

The 410 neck finish offers one and a half thread turns, providing a slightly tighter seal compared to the 400 finish. This added half turn allows for more thread engagement, resulting in improved closure strength and stability, which is ideal for products requiring enhanced sealing.

**415 Neck Finish**

A 415 neck finish has two complete thread turns. The threads on a 415 finish are generally thinner than those found on the 400 or 410 finishes, and the neck itself is typically taller. This finish is often used for containers where precise sealing and a taller neck profile are preferred.

**425 Neck Finish**

Two thread turns.

**430 Neck Finish**

A 430 neck finish offers one or two thread turns, but unlike other standard neck finishes, the threads are deeper and more pronounced. This unique design is known as a buttress thread, which is specifically engineered to help users pour the product with greater accuracy and control. The deeper threads of a 430 finish provide additional strength, making it an ideal choice for containers designed for dispensing liquids that require precision pouring, such as certain chemicals or industrial products.

Each of these thread finishes is tailored for specific container needs, ensuring a secure seal and functionality across a variety of industries. Matching the correct neck finish to the appropriate closure is critical for achieving the desired performance and ensuring the product’s integrity.

Non-Continuous Thread Finishes

Does KingStar produce custom non-continuous thread? The answer is yes. KingStar has decades of experience in customizing water cups and provides one-stop water cup manufacturing services. We can customize neck finishes of any specifications for customers. The following photos are for reference.

Neck Finishes of Best-Selling Water Bottles

Taking the markets in the United States, Canada, Australia, and Germany as examples, some of the best-selling water bottles are from brands like Hydro Flask, Hydro Cell, and Simple Modern, particularly their wide-mouth models. These bottles typically feature a 60-400 neck finish.

The popularity of these wide-mouth water bottles stems from several factors. First, the wide opening makes it easier to add ice cubes, fruits, or other flavorings, as well as to clean the bottle thoroughly. This design is especially appealing for people who prioritize hydration throughout the day or enjoy customizing their drinks.

The 60-400 neck finish, specifically, refers to the threading standard used on these bottles. The “60” represents the outer diameter of the threads in millimeters, while the “400” indicates a single thread turn around the neck. This finish allows for a secure, airtight seal when paired with compatible caps, ensuring the bottles are leak-proof and able to maintain the temperature of their contents—whether hot or cold.

In addition to their practical features, these water bottles are favored for their durability, often made from high-quality stainless steel with vacuum insulation, which keeps drinks cold for up to 24 hours or hot for up to 12. Their sleek, minimalist designs and a variety of color options have also contributed to their widespread appeal in these major markets.

These brands have established a strong presence in outdoor activities, fitness, and everyday hydration, making them popular choices for both casual users and athletes alike. The standard 60-400 neck finish across these brands ensures compatibility with a range of lids and accessories, offering users flexibility in how they use their bottles.

Bottle Neck Thread Standards

The bottle neck thread standard refers to the threading specifications used on the openings of containers, such as plastic or glass bottles, to ensure compatibility between different brands and models of bottle caps. Commonly used thread standards include the following:

-

**GPI Thread Standard (Glass Packaging Institute)**:

Primarily used for glass bottles, jars, and stainless steel water bottles. Common specifications include 13-415, 15-415, 18-400, 20-400, 22-400, 24-400, and 60-400. This standard is widely adopted for beverage and food containers, ensuring a secure seal and compatibility with various closures.

-

**PCO Thread Standard (Plastic Closure Only)**:

Mainly used for plastic bottles, such as those for mineral water and beverages. Common sizes are 28mm, 30mm, and 38mm. The 28mm size is the most frequently used, especially for small bottles like 500ml, 550ml, and 600ml. Larger sizes, like 30mm and 38mm, are typically used for 1.5L and 2L bottles.

-

**PCT Thread Standard (Plastic Closure Thread)**:

Primarily used for small-capacity plastic bottles, such as those for pharmaceuticals and cosmetics. Common sizes include 18mm, 20mm, and 22mm, with 18mm being the most frequently used.

These are just a few of the common bottle neck thread standards, but different container types, sizes, and uses may require different threading specifications. Choosing the correct neck thread standard is crucial for ensuring product seal integrity and container stability. The following sections will focus mainly on the GPI standard.

How to Make the Thread of Stainless Steel Water Bottles

The process used to create threads on stainless steel water bottles is called “threading,” and it is carried out using specialized equipment. This technique involves precisely cutting or forming the threads on the neck of the bottle to ensure that the cap fits securely and forms a leak-proof seal.

In manufacturing, threading stainless steel bottles requires high-precision machines that can handle the material’s hardness and ensure uniform thread dimensions. The equipment used in this process can either cut threads into the bottle neck or roll them into the material, depending on the specific manufacturing technique. For continuous thread finishes (such as 60-400), the threading process must be exact to ensure compatibility with standard-sized caps, ensuring that the closure aligns perfectly and provides a secure seal.

The quality of threading in stainless steel bottles is critical for several reasons:

- **Seal Integrity**: Proper threading ensures that the cap fits tightly, preventing leaks and keeping the contents insulated, whether hot or cold.

- **Durability**: Since stainless steel is known for its strength and resistance to corrosion, precision threading contributes to the overall durability and long-term use of the bottle.

- **Compatibility**: Standardized threading, such as 60-400 or other thread finishes, ensures that the bottle is compatible with a wide range of caps and accessories available in the market.

Threading is an essential step in the production of stainless steel water bottles, contributing to both functionality and user experience.

Stainless steel water bottle thread making process video as below:

Custom the Best Neck & Cap Design for Your Custom Design Drink Bottle / Jug / Cup / Drinkware / Container

This guide serves as an introduction to the complex world of neck finishes. However, there are many more options available beyond those covered here. Additionally, we can customize neck finishes in various sizes and shapes according to customer requirements.

If you have specific needs or unique design preferences, feel free to reach out to us. Our engineering team is ready to assist you in determining the most suitable bottle neck finish for your product. Contact us today to explore the options that will be bet for your drinkware/vessel/container and ensure optimal functionality and compatibility.