This article focuses on the analysis of the current situation of smart water bottles, and endeavors to present major factors that lead to the high price of intelligent water bottles. The data quoted by are unassailable as they are released by the authority. So just move on and you will find out the answer “Why Is Smart Water Bottle So Expensive?”

1. Market Situation

The size of smart water bottle market in the United States is expected to reach $30.6 million by 2026. The CAGR (Compound Annual Growth Rate) during 2021 to 2026 is forecasted to attain a staggering number of 17.3%. The aggressive market is propelled by the rising health-related consciousness of people and the growing hydration science and technology. Also, the soaring demand for smart fitness equipment such as trackers and gym accessories is enhancing the intelligent water bottle market. What’s more, it is the advanced wireless technology that plays a vital role in promoting the smart equipment and boosting the industry progressively.

2. Smart Water Bottle Components

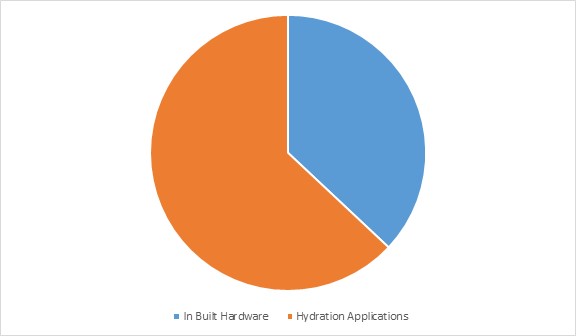

A smart water bottle usually contains three components, namely, the hydration tracking app, the in-built hardware and the bottle itself. From the perspective of the smart water bottle market, the share of the bottle itself is omitted purposefully as it is trivial compared with the hydration tracking app and the in-built hardware.

2.1 The Hydration Tracking App

The largest share (62.3%) in the intelligent water bottle market in 2020 belongs to the hydration tracking app. The app exclusively designed for the bottle accounts for nearly half of the entire R&D fees of smart water bottle companies. Most of the apps in the market can offer customers with personalized hydration goals/targets, enabling them to check out how much water they have consumed visually. Some apps can serve as your hydration keeper who will regularly remind you of drinking water, so that you will not forget it due to busy work or bad memories. Also, water bottle manufacturers have to make their apps easy to use with pleasing human-machine interaction interface, which indicates another huge expenditure.

2.2 The In-built Hardware

The hardware installed inside of the bottle holds the rest of the share in the smart water bottle market at 37.7%. The quality of this component directly influences the using experience of intelligent water bottles. The hardware mainly contains various sensors/sensor bands, thermometers of liquids, LEDs and lids/caps with a touch-sensitive screen or a normal screen. These small yet crucial tools help to monitor, measure and record how much water an user has consumed, remind he/she of regular and on-time drinking, and present information such as the real time, the temperature of the liquids and the battery status. The convenience and the healthy habit brought by the smart hardware give impetus to the consumption of smart water bottles, which in turn propels water bottle companies to further improve the technology and quality of the in-built hardware.

Smart Water Bottle Market, By Component, 2020 (%)

2.3 The Bottle

Compared with the hydration tracking app and the in-built hardware, the bottle is not so smart and contains less advanced technology. However, it also exerts influence on the performance of intelligent water bottles. Most of the smart water bottles in the market adopt stainless steel SUS304, a BPA free material that has been widely used in many industries, and some bottles for kids even use medical standards stainless steel SUS316. If equipped with double-walled stainless steel structure, a smart water bottle will boast better insulation performance and attract much more attentions.

3. Smart Water Bottle Manufacturing Processes

stainless steel water bottle manufacturing video

Smart Water Bottle Pro Manufacturing Process

Brief description: Stainless steel arrives at the factory in the form of pines and sheets –> Produce outer bottle, inner bottle and smart module –> Assembly and welding –> Vacuuming –> Decorating.

1. Manufacture Outer Bottle

1.1 Pipe cutting: Cut raw material – stainless steel pipe – to the appropriate length.

1.2 Expansion

There are basically two different ways to make stainless steel into the shape of a bottle: water expansion and stretching.

Water Expansion: Stainless steel pipes are raw material for this method. First, stainless steel pipe is put on the water expansion machine. The pipe swells into a bottle shape under the huge pressure of the water. With this method, the bottle formed is with no bottom, so a round stainless steel plate will be welded onto it to form a complete bottle.

Stretch: Stainless steel sheets are raw material for this method. First, the stainless steel sheets are cut into round plates at appropriate size, and then we use a punch press to stretch the stainless steel plate into a cylinder with a bottom.

The outer bottle can be formed by any of these two methods. Water expansion is more popular.

1.3 Separating: If using water expansion process to form outer bottle, then separating process is a must.

1.4 Shaping: Use a large press and follow the “Bottle Shaping Guide” to ensure that the pits, size and shape of the outer bottle meet the requirements.

1.5 Necking: Use a machine to squeeze the upside of the bottle to be a bottle neck.

1.6 Thread Rolling/Making: Threads are made with a special threading machine. Ensure that the thread meets requirements.

1.7 Cleaning: Removes lubricating oil and dust during molding.

1.8 Inspection

2. Manufacture Inner Bottle

2.1 Pipe cutting: Cut raw material – stainless steel pipe – to the appropriate length.

2.2 Expansion. Water expansion or stretch. The inner bottle can be formed by any of these two methods. Water expansion is more popular.

2.3 Separating

2.4 Shaping

2.5 Necking

2.6 Thread Rolling/Making (Normally if outer bottle is designed with thread, there’s no thread on inner bottle)

2.7 Cleaning

2.8 Inspection

3. Assembly (Bottle Mouth Matching)

Assemble the inner bottle and the outer bottle together by pressing machine.

4. Bottle Bottom Assembly

Assemble the bottom to the bottle by pressing machine.

5. Assembly (Bottle Mouth Welding)

Weld the inner bottle and outer bottle together to prepare for vacuum insulation. Ensure smoothness, no bumps or solder joints.

6. Assembly (Bottle Bottom Welding)

Weld the outer bottle and the bottle bottom to prepare for vacuum insulation. Ensure smoothness, no bumps or solder joints.

7. Leaking Test

Check whether inner bottle and outer bottle were well welded.

8. Vacuuming

Vacuuming with a vacuum machine.

9. Temperature Test / Insulation Test

Blow hot air into each bottle. If the outside of the bottle is kept cool, it means that the heat from the hot air will not be diverted and the bottle is vacuum insulated. On the contrary, if the bottle gets hot, there is a problem with vacuum insulation.

10. Electrolysis Polishing

Through the interaction of current and electrolyte to improve the micro-geometry of the metal surface, reduce the surface roughness of the metal, so as to achieve the purpose of bright and smooth surface of the stainless steel bottle. Surface of inner bottle to be bright and even, no watermark, yellow dot.

11. Mechanical Polishing

Polish the surface of outer bottle to ensure it is smooth and bottle mouth is smooth and bright. There must be no obvious drawing, scratching, black wire and pits.

12. Cleaning

Clean the bottle and dry it. Make the bottle ready for external coating / decorating.

13. Temperature Test / Insulation Test

Blow hot air into each bottle. If the outside of the bottle is kept cool, it means that the heat from the hot air will not be diverted and the bottle is vacuum insulated. On the contrary, if the bottle gets hot, there is a problem with vacuum insulation.

14. External Coating(surface decorating)

The bottle is now ready for external coating –powder coating or spray painting. KingStar is capable of doing both spray printing and powder coating process.

15. Pattern and Logo Printing

Print the pattern design and logo on the bottle with various techniques – screen printing, thermal transfer printing, water transfer printing, laser etching and so on.

16. Temperature Test / Insulation Test

Blow hot air into each bottle. If the outside of the bottle is kept cool, it means that the heat from the hot air will not be diverted and the bottle is vacuum insulated. On the contrary, if the bottle gets hot, there is a problem with vacuum insulation.

17. Produce the built-in electronic module

18. Test the smart functions of the smart module to ensure it works

19. Packing

After inspect each bottle, including visual inspection, Bluetooth function, reminder function and lid leak test, the bottle is place in a separate bag for packaging.

4. Smart Water Bottle Transportation & Distribution Channel

4.1 Transportation Channel

Since about 95% of the world’s smart water bottles comes from China, the United States has to import them from countries like China. So, how to transport water bottles to U.S.? There are mainly four transportation means adopted in foreign trade: transportation by sea, by air, by track, and by truck. Smart water bottle is not so profitable and is perfect for either sea shipment or truck transportation. However, truck transportation is frequently adopted in China-Europe trade and is not applicable for China-U.S. trade (the Pacific Ocean eliminates such a possibility). Then the only way left is sea shipment.

The covid-19 that caught the world all by surprise is impeding the smart water bottle transportation severely. For one thing, Chinese manufacturers could not offer adequate supply due to the lockdown policy and social distancing practices. For another, many international shipping lines raised their rates or even shut down the lucrative routes, which actually increased the hidden cost of smart water bottles. Water bottle companies in the United States also were faced with lengthened delivery time as the ports were crowded with carriers of all sizes. All these factors result in the high price of smart water bottles. Currently, China is in better shape than it was a year ago and water bottle OEM manufacturers are able to ship smart water bottles with high quality in bulk to the United States and other countries. But the shipping rates remain high.

4.2 Distribution Channel

When smart water bottles arrive in the United States, water bottle companies have to deliver them to customers. The online distribution channel is mostly used as there are not many smart water bottles available in offline shops and stores. It is anticipated that the online distribution means will increment at a CAGR of 8.9% as the online distribution is also favored by people who can just stay at home without going out amid the pandemic situation.

5. Smart Water Bottle Markets

At present, North America takes the dominant position in the intelligent water bottle market, taking up a share of over 35%, followed by Asia Pacific and Europe. The soaring need for high-tech smart water bottles and the increasing purchasing power of customers around the world are giving a continuous impetus to the advancement of smart water bottle markets. Moreover, the high obesity rates and dehydration issues also urge people to live a healthier hydration life, which also contributes to the booming of these potential markets. It is reasonably guessable that the high price of intelligent water bottles also comes down to both the prosperity of the market and the popularity of customers.

6. Smart Water Bottle Market Propellers

6.1 Increasing Health Awareness

The contemporary fast-paced lifestyle yields splendid economic fruits yet also damages people’s health. As a result, many office men and ladies would sit at their workstations whole day long without adequate exercise and drinking, and some of them even fall ill due to various factors. Luckily, people’s health awareness is increasing and they are placing high value on smart water bottles. According to IHRSA (International Health, Racquet, and Sportsclub Association), the revenue of health industry around the world reached $94 billion in 2018, which reflected the good change toward a healthier lifestyle. People are willing to purchase expensive smart water bottles for their health, and intelligent water companies can even reasonably increase the price as long as their products are premium and conducive to people’s health.

6.2 Adoption of Emerging Technology

The adoption of emerging technology has been seen in a spectrum of fitness equipment such as smart bands, fitness trackers and smart watches. These equipment greatly attract fitness enthusiasts’ and normal people’s attention, and has ushered in a new era of intelligent gears. While they are beneficial to cultivating a healthy lifestyle and propelling the smart water bottle market, the high cost & price of them should also be mentioned. The intelligent module of smart water bottle is complicated and requires high technology and high precision. It is unavoidably pricy and is also partly the reason why most of the smart water bottles are expensive.